How sharp is the tungsten needle?

In the extraordinary world of nanotechnology, a single atom has become the ultimate precision tool. The tungsten needle—recognized by the Guinness Book of World Records—represents humanity’s most remarkable achievement in material science, pushing the boundaries of what’s possible at the smallest scales imaginable.

Quick Answer

A tungsten needle can be sharpened to an ultra-fine tip with a radius as small as 1 nanometer, sometimes even down to a single atom-0.193 nm tip radius. Achieved through electrochemical etching or precision grinding, it is essential for semiconductor, and microdissection, offering durability, heat resistance, and wear resistance.

Table of Contents

- Defining sharpness in Tungsten Needles

- Electrochemical Etching Technique

- Alternative Fabrication Methods

- Technical Specifications and Performance Metrics

- Scientific Applications

- Atomic-Resolution Imaging

- Material Characterization

- Nanoscale Manipulation

- Biomedical Research

- Technological Limitations

- Comparative Analysis

- Yolo Company Introduction

Defining Sharpness in Tungsten Needles

When discussing the sharpness of tungsten needles, two key metrics come into play:

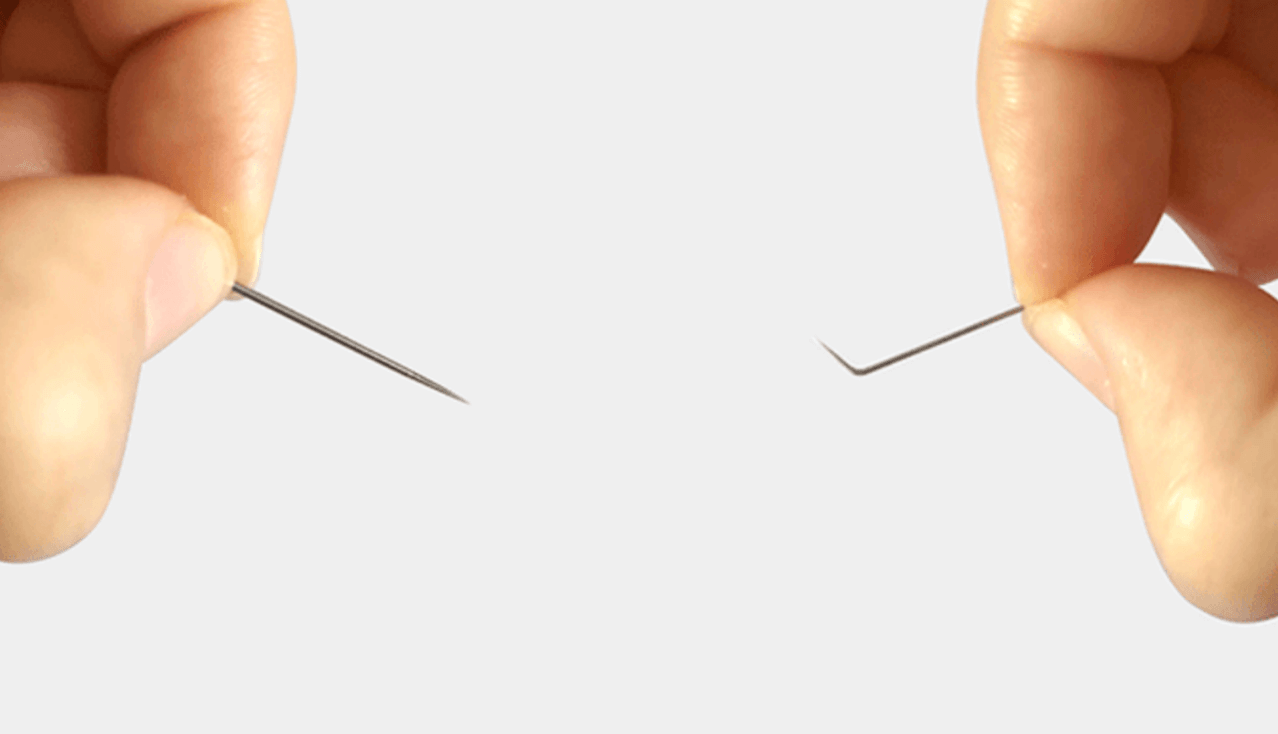

Tip radius: This is the primary measure of a needle’s sharpness, typically measured using scanning electron microscopy (SEM). State-of-the-art tungsten needles can achieve a tip radius as small as 0.193 nm, which is comparable to the dimensions of individual atoms. This extreme sharpness allows for unprecedented precision in various applications.

Taper angle: The angle at which the needle narrows to its point is crucial for certain applications. For high-precision work, taper angles are typically less than 10 degrees, achieved through carefully controlled etching processes.

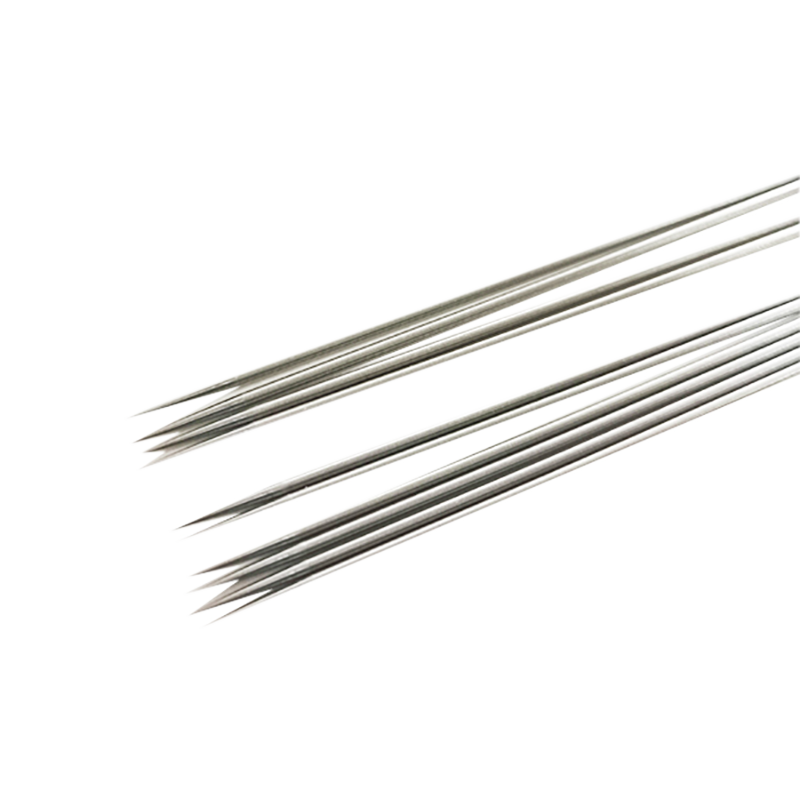

Yolo’s sharpest tungsten needle

Unlike cutting blades that rely on wedge angles for their effectiveness, needle sharpness prioritizes tip geometry due to their primary function of probing rather than cutting. This focus on tip radius and taper angle allows tungsten needles to achieve levels of precision that are unattainable with traditional cutting tools.

Electrochemical Etching Technique

The gold standard for creating ultra-sharp tungsten tips involves a sophisticated electrochemical etching process:

Material selection: The process begins with 99.95% pure tungsten rods, ensuring minimal impurities that could affect the final tip geometry.

Etching setup: The tungsten rod is immersed in a sodium hydroxide (NaOH) solution, typically with a concentration between 1M and 3M.

Electrochemical reaction: A DC current of 2-10V is applied, creating a controlled dissolution of the tungsten. The etching occurs more rapidly at the air-electrolyte interface, naturally forming a sharp tip.

Meniscus formation: As etching progresses, a meniscus forms around the rod, concentrating the etching action and further refining the tip shape.

Cut-off mechanism: Advanced setups include an automatic cut-off system that detects when the lower portion of the wire drops, immediately stopping the etching to prevent over-etching of the tip.

Field-directed sputtering: For the sharpest needles, an additional step of nitrogen ion bombardment in vacuum chambers refines tips to atomic-scale sharpness.

Quality control: The final step involves SEM validation to confirm tip radii below 1 nm.

This method achieves 10 times greater tip consistency compared to mechanical grinding techniques, making it the preferred choice for high-precision applications.

Alternative Fabrication Methods

While electrochemical etching is the preferred method for creating the sharpest tips, other techniques are used for specific applications or when different tip geometries are required:

While electrochemical etching is the preferred method for creating the sharpest tips, other techniques are used for specific applications or when different tip geometries are required:

Mechanical grinding:

Tip Radius: 50-100 nm

Applications: Industrial probes, less sensitive measurements

Limitations: Can introduce surface defects, less consistent tip geometry

Laser ablation:

Tip Radius: 20-50 nm

Applications: Medical devices, specialized industrial probes

Limitations: Potential for thermal distortion of the tip

Focused ion beam (FIB):

Tip Radius: <5 nm

Applications: Research microscopy, nanofabrication

Limitations: High cost, time-consuming process

Each of these methods has its place in the production of tungsten needles, with the choice depending on the specific requirements of the application, production volume, and cost considerations.

Technical Specifications and Performance Metrics

The performance of tungsten needles is characterized by several key specifications:

Tip radius: Ranges from the record-breaking 0.193 nm (single-atom sharpness) to 1 µm for more robust industrial probes.

Taper angles: Typically between 3° and 15°, depending on the application and manufacturing process.

Surface roughness: After polishing, surface roughness can be reduced to less than 0.5 nm Ra (average roughness).

Breakdown voltage: For electronic applications, tungsten needles can withstand voltages exceeding 100 V/µm.

Mechanical strength: Despite their sharpness, tungsten needles maintain significant strength, with tensile strengths up to 1500 MPa.

These specifications contribute to the needle’s performance in various ways:

Sharper tips (smaller radii) allow for higher resolution in imaging and more precise manipulation of individual atoms or molecules.

Smoother surfaces reduce the risk of contamination and improve the consistency of measurements.

High breakdown voltages enable the use of tungsten needles in high-energy physics experiments and advanced electronic testing.

Scientific Applications of Atomic-Scale Precision

1. Atomic-Resolution Imaging

Scanning Tunneling Microscopy (STM) transforms the tungsten nanoneedle into a revolutionary imaging tool. By generating quantum tunneling currents between its tip and a surface, scientists can now visualize material structures with unprecedented atomic-level detail. This technique allows researchers to map individual atomic arrangements, revealing intricate surface topographies that were previously invisible.

The mechanism is elegantly simple yet profoundly complex: a voltage applied to the needle creates a current that “jumps” to the surface, with variations in current revealing the atomic landscape. This method has been particularly groundbreaking in studying complex materials like superconductors and quantum materials.

2. Surface Topography and Material Characterization

Atomic Force Microscopy (AFM) elevates the tungsten needle’s capabilities even further. By measuring minute surface forces—including van der Waals and electrostatic interactions—these needles create three-dimensional topographical maps with sub-nanometer precision.

The true marvel lies in their ability to interact with delicate structures. Researchers can now manipulate nanoparticles and biological molecules like DNA with minimal risk of damage, opening unprecedented avenues in nanoscale research and medical diagnostics.

3. Phonon Scanning and Material Dynamics

Beyond visual mapping, these ultra-sharp tungsten needles can detect vibrational energy quanta known as phonons. This capability allows scientists to explore the thermal and mechanical properties of materials at an atomic scale, providing insights into fundamental material behaviors that were previously unobservable.

4. Semiconductor and Nanotechnology Applications

![]()

In the realm of semiconductor testing and nanofabrication, tungsten needles have become indispensable tools. They enable:

- Precise electrical property measurements of microchips

- Individual atom deposition and removal in nanoscale manufacturing

- Ultraprecise probing of electronic characteristics

5. Biomedical Research and Innovations

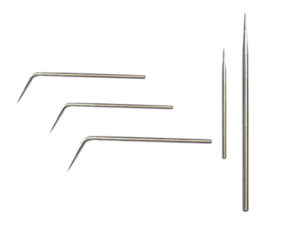

Yolo’s sharpest tungsten needle for medical use (microdissetion and RF ablation)

The biomedical potential of these atomic-scale needles is equally revolutionary. Electrochemically sharpened tungsten needles offer:

- Minimally invasive procedures with near-zero tissue resistance

- Targeted drug delivery mechanisms using nanoparticle coatings

- Unprecedented precision in cellular and molecular interactions

Comparative Analysis of Precision Cutting Tools

| Material | Edge Radius | Primary Application | Key Limitation |

|---|---|---|---|

| Tungsten Nanoneedle | 0.193 nm | Atomic imaging, research | Extremely fragile |

| Obsidian Scalpel | 3 nm | Surgical incisions | Rare, brittle material |

| Sapphire Scalpel | 25 nm | Precision surgical cuts | High cost |

Find Your Sharp Tungsten Needle Here!

YOLO Company Introduction

Building upon the remarkable properties of tungsten needles, YOLO introduces high-precision tungsten needle solutions tailored for advanced scientific and industrial applications. Our specialized tungsten needles offer unprecedented capabilities across multiple critical domains.

Comprehensive Applications

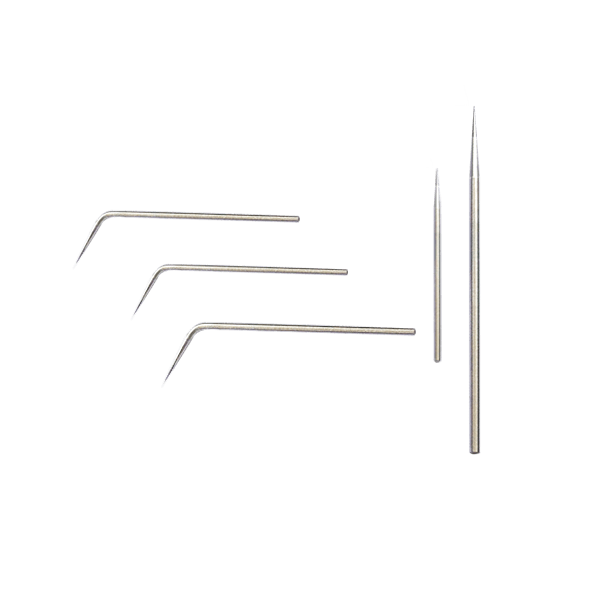

YOLO’s fine tungsten needles, with tip sizes starting from 5 microns, excel in diverse and demanding fields:- Medical Minimally Invasive Surgery: Ultra-fine tips enable extremely precise surgical interventions with minimal tissue damage.

- Ablation Electrodes: Precise electrical targeting for medical procedures, particularly in cancer treatment and neurosurgery.

- Semiconductor Testing Probes: High-precision electrical characterization of microchips and electronic components.

Manufacturing Excellence

At YOLO, we control the entire production process from raw material refinement to final machining, ensuring stable quality and high precision. Our tungsten needles are available in ultra-fine sizes starting from 5µm, meeting the most demanding application requirements. We offer comprehensive custom machining services, including:- Precision bending

- Specialized slotting

- Advanced coating techniques

- Precision grinding

- Custom tip shaping

Sharpest Tungsten Needle, Yolo's Own Raw Materials

Elevate your work performance with our sharpest tungsten needles by Yolo’s own tungsten raw materials! Ultra fine tip 5um with factory direct price!