Product

Solve your weld problems from Our Pre-ground Tungsten Electrode

With Factory Direct Price

Struggling with unreliable Pre-ground Tungsten TIG Electrodes with high cost?

Manually ground electrodes bring issues like inconsistent arcs, variable weld quality, contamination risks, and frequent downtime.

Even worse, unqualified pre-ground electrodes suffer from same problems due to inadequate quality control, low impurities, and improper tolerances

Yolo’s pre-ground tungsten TIG electrodes solve these issues, delivering consistent performance, clean surfaces, and increased productivity. Plus, with our factory direct prices, you get quality and value.

Keep reading to see how Yolo can improve your welding!

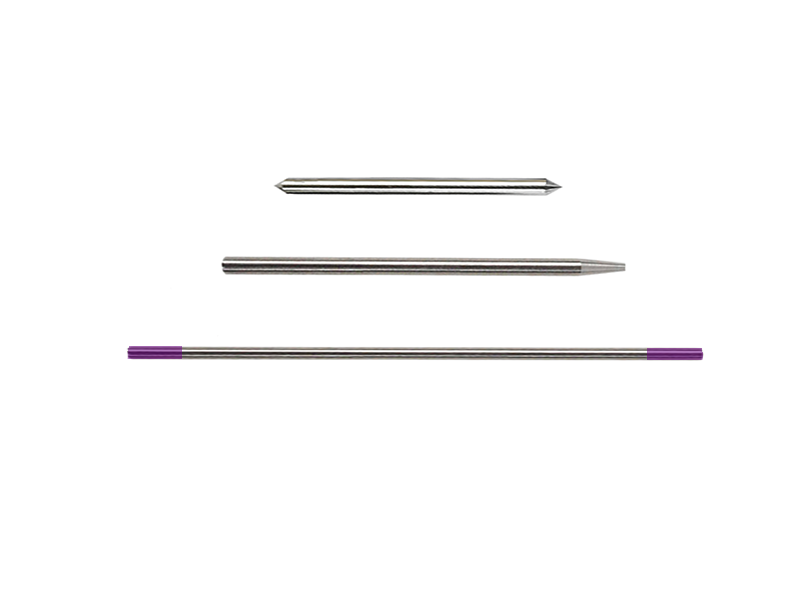

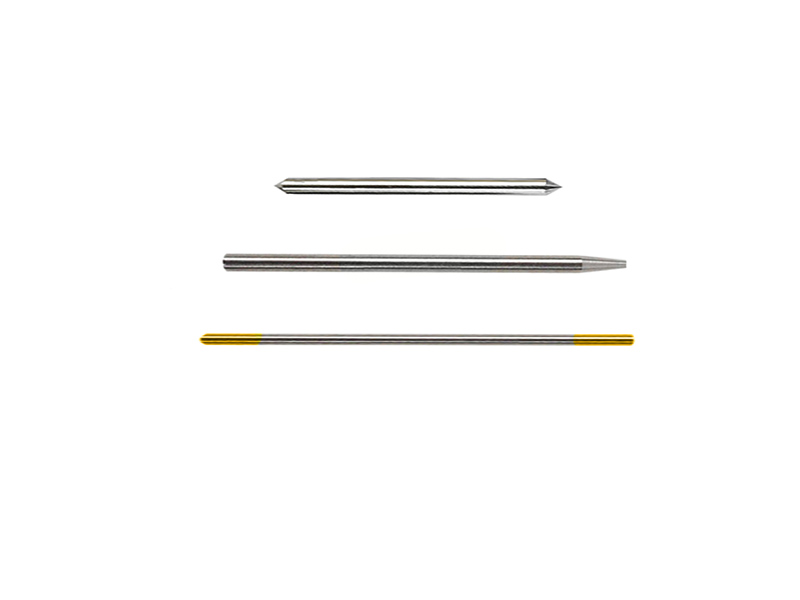

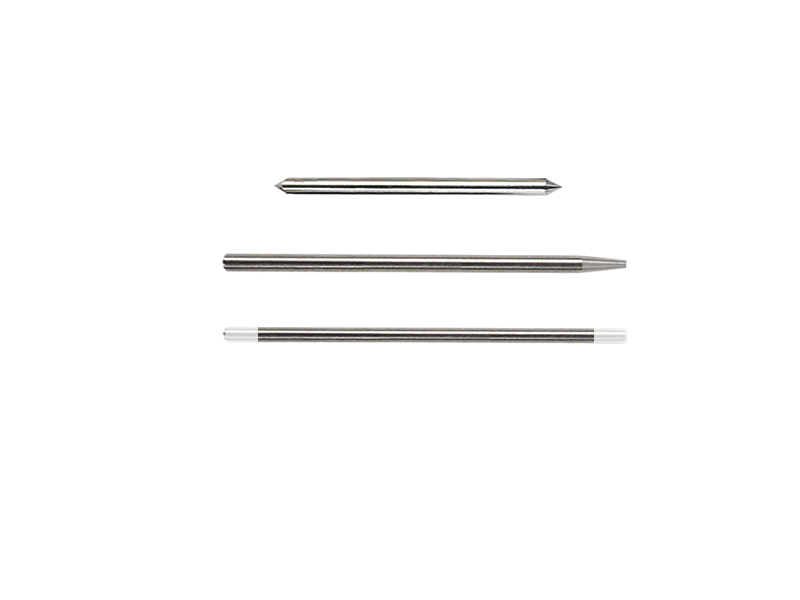

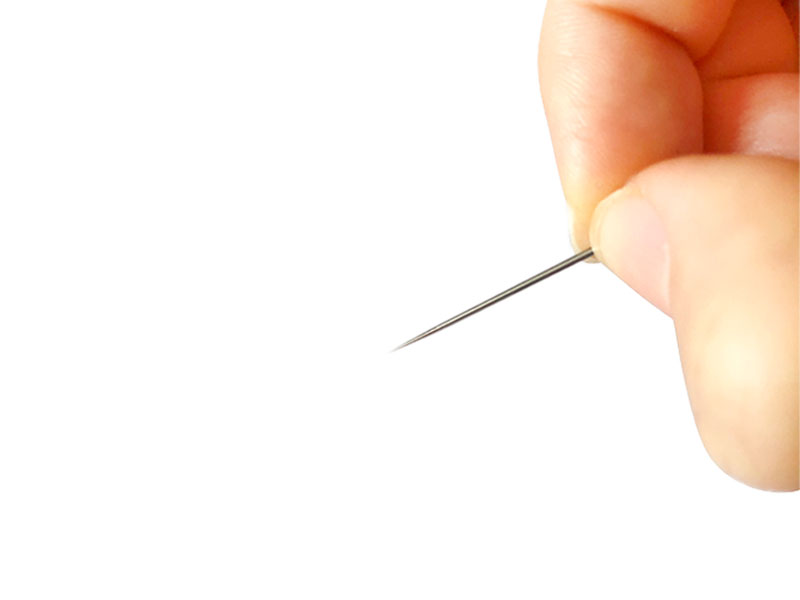

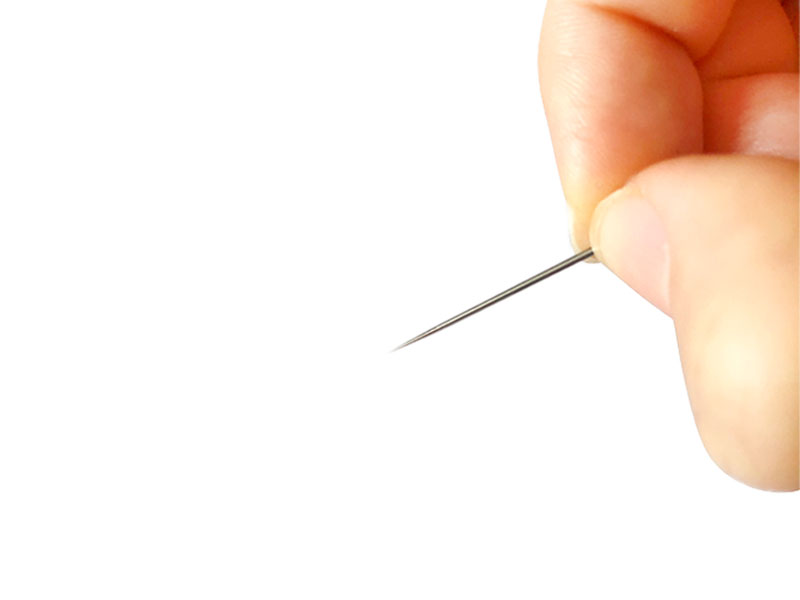

Check out our tungsten needle

Take a peek inside our Tungsten Needle

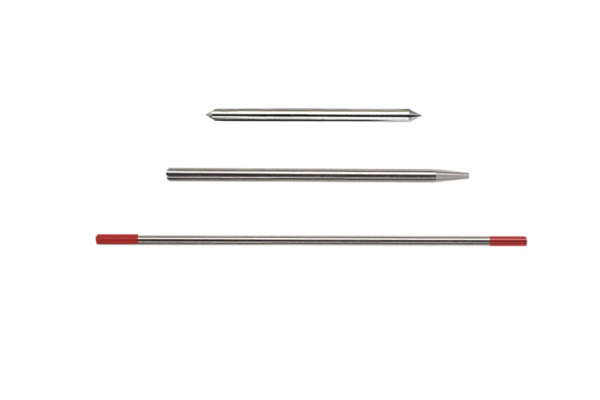

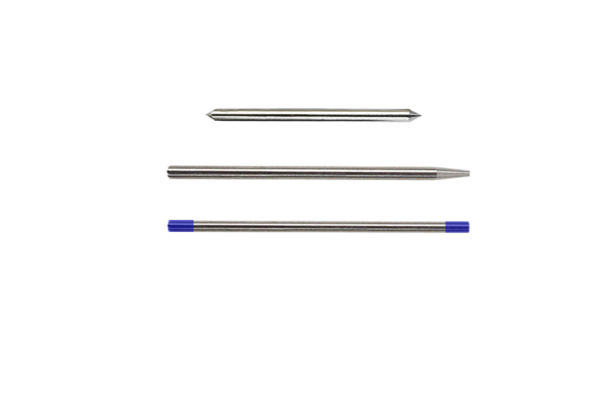

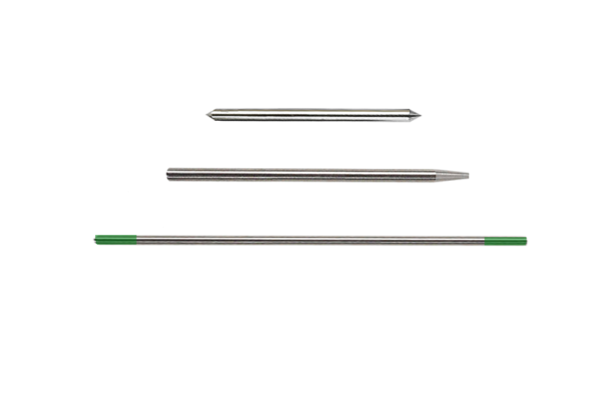

Materials of Pre-Ground Tungsten Tig Electrodes

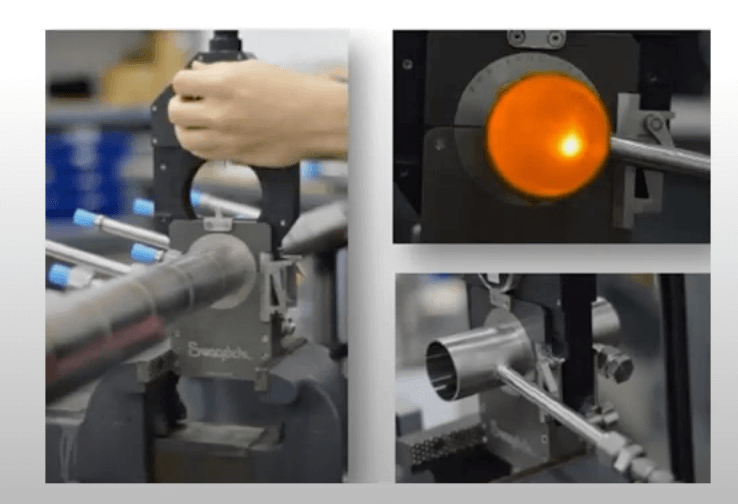

YOLO Grinding Service

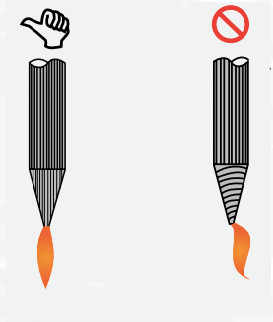

1. Longitudinal Grinding Direction

Unlock superior welding performance with our longitudinally pre-ground tungsten electrodes, you will get:

- Stable Arc

- Precision Tip

- Longer Life

- Ensures consistent, high-quality welds

2. Strict Tolerance

Your orbital welding systems will demand strict tolerances and uniform quality standards, right?

Our tungsten TIG welding stinger electrodes can meet all the high requirements set by orbital manufacturers , also includes high precision requests in medical use.

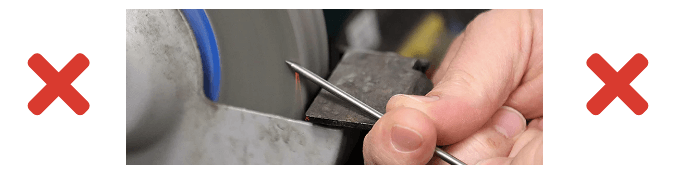

3. Say No To Rough Grinding!

4. Customization Service

The customizable grinding services available to meet your specific needs and unique specifications, providing tailored solutions for your welding requirements, angle, tip diameter, length, even tip shape.

Orbital Welding

What is Orbital Welding?

- Orbital welding is a specialized area of welding

- The “orbital” process is the path the tungsten tig welding electrode takes around the weld joint.

- Used to meet technical requirements of a specific weld.

- Importance of orbital welding: Precision; Consistency; Accessibility; Productivity;

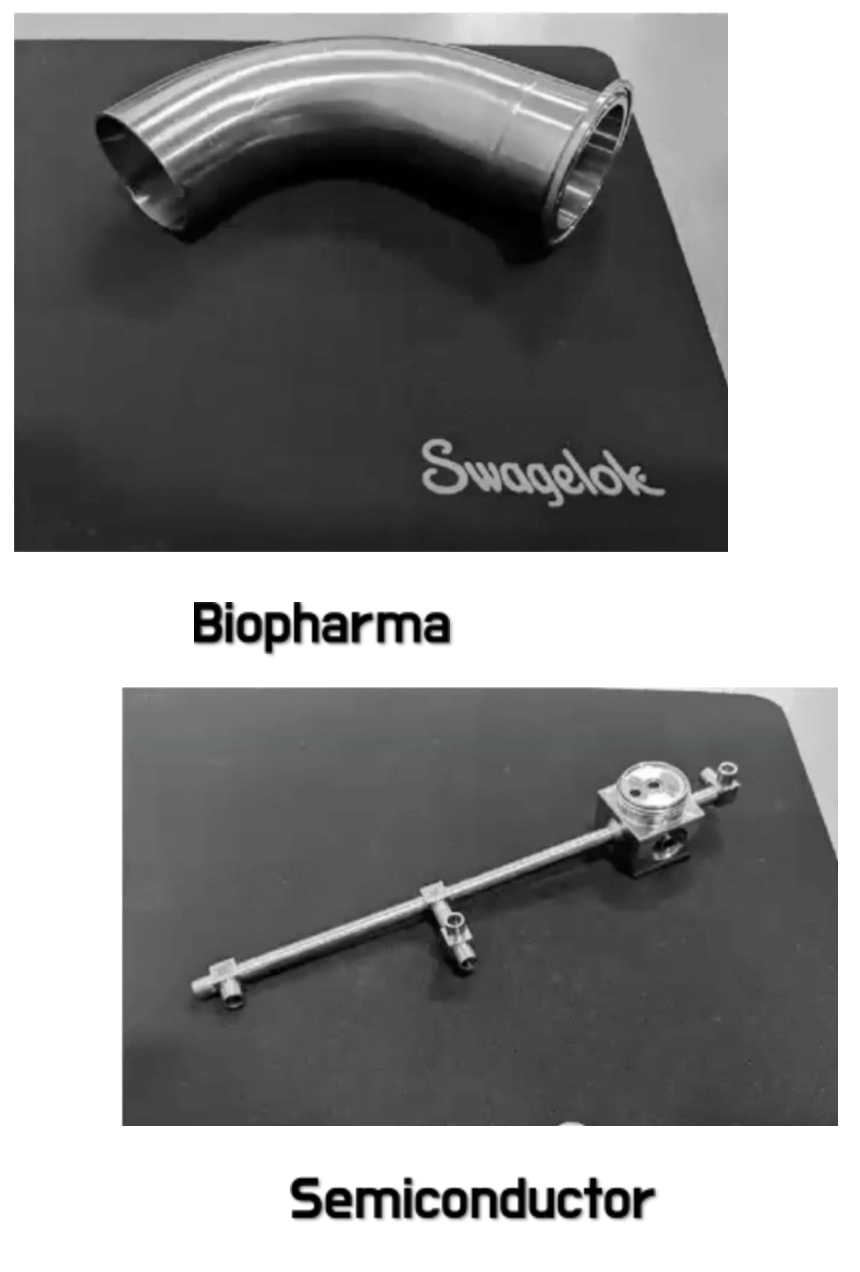

Where is Pre-sharpend tungsten needle of Orbital Welding use?

Biopharmaceutical

Aerospace

Food Beverage & Dairy

Sanitary

Power Generation

Oil & Gas

Services

Are you experiencing any of these 7 problems when orbital welding?

When using manually ground tungsten electrodes in orbital welding, several issues may arise due to variations in tip geometry and surface quality:

- Inconsistent Arc Stability

- Variable Weld Quality

- Contamination Risks

- Difficulty in Arc Starting

- Increased Downtime

- Surface Defects

- High overall cost

Let Yolo's Pre- Ground Tungsten Electrodes Save Your Welding!

Manually Ground VS Pre-Ground

Manually Ground:

Pre Ground by Yolo

Improve Your Productivity

Pre-sharpened means ready-to-use, the sharpened electrode eliminates the need for frequent adjustments or re-grinding, reducing downtime and increasing overall productivity for your team.

Cost-Effective

Pre-ground electrodes reduce the need for additional labor, equipment, and consumables, leading to lower operational costs and simpler welding operations for your business.

High weld consistency

Our pre-ground electrodes provide you with stable arcs and uniform weld quality, reducing variability and improving weld consistency.

Defect-free surfaces

High-quality grinding processes produce defect-free surfaces, lowering the risk of weld contamination for you.

Easy Arc Initiation

Precise tip geometry ensures reliable arc starting and maintenance, preventing interruptions and ensuring a smooth welding process.

Have you encountered any of these 6 problems when buying pre ground electrode with POOR QUALITY?

Unstable Arc

Inconsistent Tip Shape: Although some electrodes are labeled as pre-ground, their tip shape may be inconsistent, resulting in an unstable arc and variable weld quality.

Poor Surface Finish

The grinding process might leave rough or uneven surfaces on the electrodes, which can increase the risk of contamination and negatively affect weld integrity.

Cracks

Lack of stringent quality control measures can result in electrodes with various defects, such as cracks, chips, or other physical deformities.

Low-Grade Materials

Some electrodes might be made from inferior materials or the incorrect alloy composition, that do not provide the required durability and performance for high-precision welding tasks.

Improper Tolerances

Electrodes with improper tolerances, such as tips, length, angle tolerance you have, might not fit correctly into the welding equipment? And causing issues with alignment and weld consistency..

Inconsistent Batch Quality

Some suppliers may deliver pre-ground tungsten electrodes with varying quality from batch to batch, leading to uncertainty and potential issues with weld performance and reliability.

Let's Yolo's Pre-Ground Tungsten Electrodes Save All Your Poor Problems!

Superior but Low Cost Source

Whether you need 2% Ceriated, 2% Lanthanated, or 2% Thoriated Tungsten, you will receive TIG welding tungsten needles with precise alloy composition and material certification from Yolo, since we are the source factory of raw materials powder! No shortcuts, no substandard products—only the highest quality electrodes.

Consistent Quality

Can’t accept lot-to-lot variation? You can get uniform quality pre-ground tungsten needles, guaranteeing consistent performance in every weld. 100% fully inspected by the complete QC system. Including interior structure inspection, metallographic analysis and projector test, etc. Any defects such as cracks and chips needle will get rejected. To make sure your weld results are perfect and consistent every time.

Clean Welds

Say goodbye to contamination risks. You can choose Ra finishes with different cost, with longitudinal, mirror-polished grinding in the dust-free workshop to meet high-quality welding standards. Ensure your welds are clean and perfect every time.

Stable Arc & Weld Quality

We inspect every tip with advanced projectors to ensure the tolerance and size are perfect, such as tips, angles, length tolerance. You will achieve flawless welds every time with our electrodes, featuring consistently precise tip shapes that provide stable arcs and reliable weld quality.

0 Time Cost, Efficient Welding

While our pre-ground electrodes may have a slightly higher initial cost, they save you money in the long run by reducing your overall welding expenses. You’ll experience less downtime and rework, leading to greater efficiency and cost savings in your welding operations.

Stable Arc & Weld Quality

We inspect every tip with advanced projectors to ensure the tolerance and size are perfect, such as tips, angles, length tolerance. You will achieve flawless welds every time with our electrodes, featuring consistently precise tip shapes that provide stable arcs and reliable weld quality.

Upgrade Your Welding Today!

Experience Precision, Consistency, and Quality with Our Pre-Ground Tungsten Electrodes

- Consistent Quality: Enjoy uniform performance in every weld.

- Precise Tip Geometry: Achieve flawless welds every time.

- Superior Surface Finish: Ensure cleaner welds with less contamination.

- Custom Sizes Available: Including micron and nanometer sizes for your precise needs.

- Cost-Effective: Save money with reduced downtime and rework.

Don’t Settle for Less. Enhance Your Welding Operations Now!

Contact Us Today for a customized quote or more information.