Product

Plasma spray electrodes

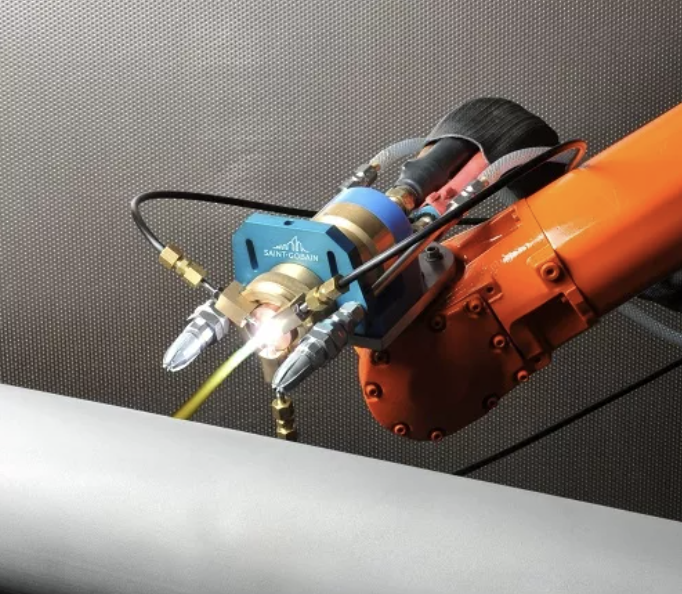

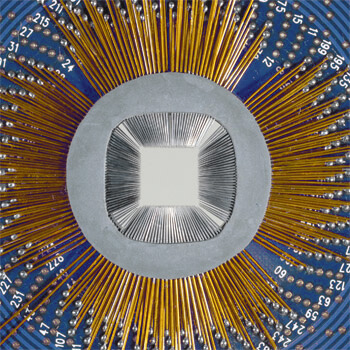

With left hand competitive labor cost, right hand German quality standard, the produced plasma anode, plasma cathode, hollow anode, and nozzle in tungsten-copper materials, through NDB technologies, become a good partner of vacuum plasma spray gun.

What Is a Plasma Spray Electrode?

A plasma spray electrode is a tungsten-based consumable used in thermal plasma spray systems to generate a stable, high-temperature plasma arc. It enables metal or ceramic powders to melt and accelerate toward the substrate, forming durable protective coatings in aerospace, medical, and industrial applications.

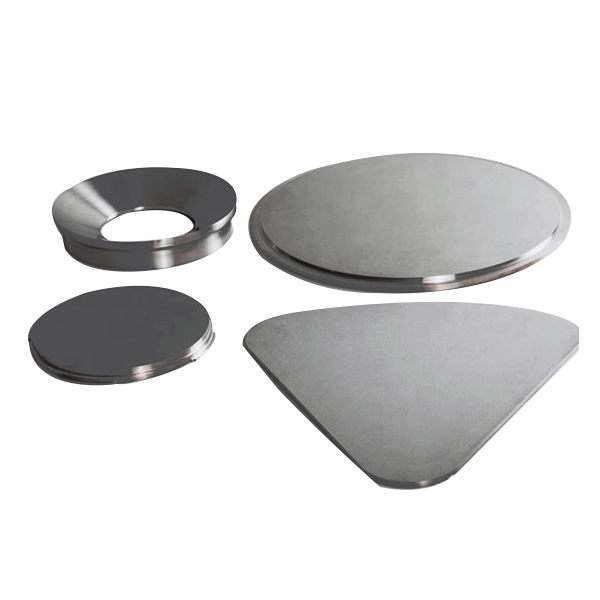

Plasma Spray Electrodes

Long Lifetime · Stable Arc · Reliable Coating Performance

High-performance plasma spray electrodes designed for extreme thermal spray environments. Built to deliver stable arc ignition, superior arc-erosion resistance, and long service life — helping you reduce downtime and total spraying cost.

- ● Arc-erosion-resistant tungsten–copper structure

- ● Easy ignition & stable plasma plume

- ● Strict quality control for batch consistency

- ● Proven on industrial plasma spray lines

Product Gallery

Why Plasma Spray Electrode Quality Matters

In plasma thermal spraying, the electrode is one of the most stressed consumable components. Poor electrode quality often leads to unstable arc ignition, rapid erosion, frequent replacement, coating inconsistency, and unplanned downtime.

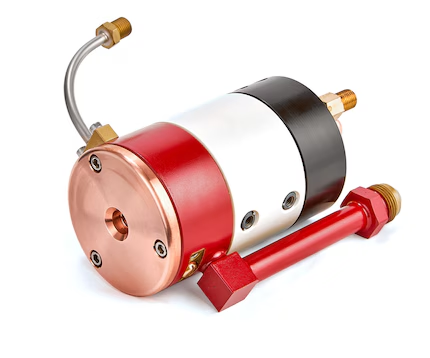

Our Engineering Solution

We use rare-earth tungsten tips (Ce-W, La-W, Th-W) combined with a copper alloy rod, bonded into a single integrated structure using vacuum NDB (Non-Defective Bonding).

This design ensures excellent heat transfer, fast heat dissipation, stable arc behavior, and controlled wear — significantly extending electrode service life under extreme plasma spray conditions.

NDB (Non-defective Bonding) by Yolo

Key Features & Operator Benefits

Arc-Erosion Resistance

Optimized tungsten–copper structure resists arc erosion under continuous high-temperature plasma spraying, delivering longer service life and fewer changeovers.

Easy Arc Ignition

Rare-earth tungsten tips provide excellent electron emission, enabling fast ignition, lower start-up voltage, and stable plasma formation.

High Quality Control

Strict raw material inspection, controlled bonding process, and final dimensional and performance checks ensure batch-to-batch consistency.

Smooth & Predictable Operation

Stable arc behavior and predictable wear patterns make daily operation easier for technicians, reducing interruptions and production stress.

Designed for Extreme Plasma Spray Conditions

Our tungsten-copper plasma spray electrodes withstand operating environments exceeding 10,000 °C, while enduring severe thermal shock and mechanical stress during continuous spraying.

This ensures complete melting of metal or ceramic powders, high-velocity particle acceleration, and uniform, high-quality coating deposition.

Materials & Structure

| Component | Specification |

|---|---|

| Tip Materials | WCe / WC20 · WLa10 / WLa20 · WTh / WT20 |

| Rod Material | High-conductivity copper alloy |

| Bonding | Vacuum NDB one-piece bonding |

System Compatibility

Our plasma spray electrodes are designed to be compatible with a wide range of industrial thermal spray systems and plasma spray guns used worldwide

Thermal Spray Processes

- Atmospheric Plasma Spray (APS)

- Vacuum Plasma Spray (VPS)

- Low Pressure Plasma Spray (LPPS)

Compatibility Scope

- OEM replacement plasma spray electrodes

- Customized designs based on drawings or samples

- Suitable for metal and ceramic powder spraying

If you are unsure about compatibility, our engineering team can review your spray gun modeland operating parameters to recommend the most suitable electrode solution.

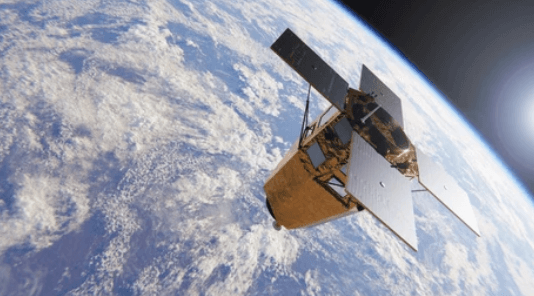

Typical End Users

Our plasma spray electrodes are trusted by professionals operating high-demand thermal spray systems across multiple industries.

Thermal Spray Service Providers

Companies specializing in industrial coating services for wear, corrosion,

and thermal protection.

Aerospace & Energy Manufacturers

Manufacturers of turbine components, aerospace parts, and high-temperature

mechanical systems.

Medical & Precision Coating Companies

Companies applying plasma coatings for medical implants and precision-engineered components.

Semiconductor & Electronics Industry

Equipment manufacturers requiring stable, contamination-controlled plasma spray coatings.

OEM Equipment Manufacturers

Plasma spray gun and thermal spray equipment manufacturers seeking reliable electrode suppliers.

Frequently Asked Questions

Are your plasma spray electrodes compatible with imported spray guns?

Yes. Our electrodes can be manufactured as OEM replacements or customized versions

based on drawings, samples, or technical specifications of imported spray guns.

Can you provide samples for testing before bulk orders?

Yes. We support sample testing for qualified projects to verify arc stability,

electrode life, and compatibility with your plasma spray process.

How do your plasma spray electrodes compare with imported brands?

Our electrodes deliver comparable or longer service life, stable arc performance,

and consistent quality, while offering factory-direct pricing and flexible customization.

What information is needed for a quotation?

Typically, we require the spray gun model, electrode dimensions or drawing,

material preference, and estimated annual usage.

Top Grade Plasma Spray Electrode

Get premium plasma spray electrodes directly from our factory in China. We offer OEM/ODM support, custom designs, and competitive pricing to meet your production needs.