Product

NDB Resistance Spot Welding Electrode

NDB (non-defective bonding) electrodes are created using a high-vacuum bonding technique that forms a seamless joint—no filler materials, no voids, no weak points. Using copper, CuCrZr as shaft, tungsten, molybdenum, WLa, TZM etc as tips. This method produces a highly conductive, ultra-strong bond with tensile strength > 120MPa.

Advanced Micro Resistance Spot Welding Electrodes

NDB Resistance Spot Welding Electrode

Tungsten & Molybdenum Base

Purity 99.95% Tungsten & Molybdenum Base

Tungsten Back-cast Copper Base

The Game-Changer in Spot Welding

“Experience the pinnacle of welding precision with our micro-resistance spot welding electrodes. Combining the strength of tungsten and molybdenum with innovative NDB bonding technology, these electrodes deliver:

- Exceptional durability to reduce wear and tear

- Consistent, precise welds on ultra-thin materials (.0005”–.005” thickness)

- Superior heat dissipation and conductivity for challenging welding environments

Whether in automotive, electronics, or battery production, our electrodes ensure performance you can rely on.

Key Features & Customer Benefits

Why Our Electrodes Stand Out?

Customizable Solutions

Any machinig servies are availbe to meet all your design requirements.

Seamless NDB Bonding

Copper and refractory metals like tungsten and molybdenum are bonded without seams or defects, achieving a connection strength of >130 MPa.

High Precision

Tip accuracy down to 0.05 µm ensures reliable welds on delicate components.

Wide Material Compatibility

Ideal for tungsten, molybdenum, stainless steel, and alloys like Inconel and nichrome.

Smooth finish:

The electrode end has high machining accuracy and a smooth finish below Ra0.8

Advanced Densification Process

Electrodes feature a high-density, uniform internal structure, reducing risks of cracks or defects.

Electrodes Materials Multiple Choices

Tungsten and molybdenum tips: Withstand extreme temperatures, maintain shape, and prevent deformation.

- WLa (wolfram-lanthanum alloy)

- WCu (wolfram-copper alloy)

- TZM (Titanium Zirconium Molybdenum)

- Pure Tungsten (99.95%)

- Pure Molybdenum (99.95%)

Copper bases: Enhance heat conductivity and durability.

- CuCrZr (chromium zirconium copper

- OFC (oxygen-free copper)

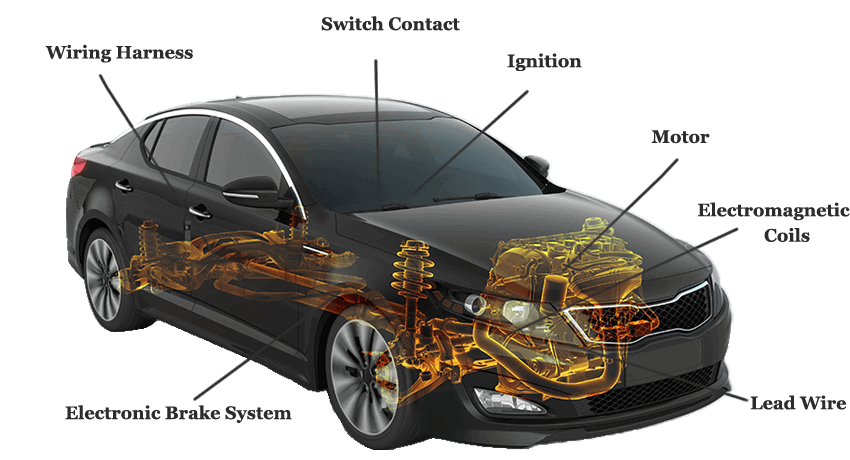

Tailored for Your Industry

Automotive Manufacturing

EV battery tabs, lightweight components, and wiring harnesses.

Electronics Production

Circuit boards, sensors, and connectors.

Battery Assembly

High-capacity lithium-ion battery tabs and connections.

Medical Device Welding

Micro-dissection tools and minimally invasive equipment.

Precision Across All Scales of Welding

Our electrodes cater to a broad range of spot welding applications

- Large-Scale Welding: Common in automotive industries for welding steel and stainless steel in thicknesses from .016” to .062”.

- Small-Scale Welding: Ideal for advanced alloys such as molybdenum, tungsten, and nichrome in thicknesses of .005” to .020”.

- Micro-Scale Welding: Perfect for high-tech industries like electronics, medical devices, and telecommunications, handling ultra-thin materials from .0005” to .005”.”

Compatible Welding Systems

Our electrodes are compatible with a wide range of micro resistance welding systems, ensuring precision and reliability:

- Transistor Welders: Optimal for super-fine wires and sensitive micro components, such as Avio MCW-700 and MCW-750 systems.

- Capacitor Discharge Welders: Suitable for less sensitive micro welding tasks.

- Inverter Welders: Reliable for moderate precision needs.

Compatible with brands including Palomar, Hughes, Unitek, Avio, MacGregor, and Sunstone Engineering.”

More about YOLO

- Raw materials & Machining Cost

Yolo, as a professional manufacturer of tungsten-base resistance welding electrode, you could save procurement costs from the source. Because we start production from raw material APT powder and meet Japanese and German market standards. But you will benefit a lot from the location of the factory, China.

-

- Delivery on time

Complete order management system and rich production experience enables customer orders in an orderly manner. Our annual customer complaint rate is less than 1%.