Why Are Tungsten and Molybdenum NDB Electrodes the Best Choice for EV Battery Tab Resistance Welding?

Tungsten and molybdenum NDB electrodes are ideal for EV battery tab resistance welding due to their superior heat resistance, high conductivity, long lifespan, and seamless bonding, ensuring consistent, precise welds with minimal maintenance.

Table of Contents

- Introduction

- Electrode Material Structure: Shaft vs. Tip

- What is NDB Technology?

- Comparison: NDB Electrodes vs. Solid Copper and Conventional Brazed Electrodes

- Performance of Tungsten, Molybdenum, WL10, and TZM Tips in Battery Tab Welding

- Application Benefits in EV Battery Tab Welding

- 6.1 Consistent Weld Quality

- 6.2 Extended Electrode Life

- 6.3 Superior Heat Management

- 6.4 Clean, Reliable Welds

- 6.5 Cost Efficiency

- 6.6 High-Speed Automation Compatibility

- 6.7 Versatility Across Tab Materials

- 6.8 Enhanced Safety and Reliability

- Yolo NDB Electrode Solutions

- Conclusion

Introduction

With the rapid adoption of electric vehicles (EVs), battery pack quality and reliability have become critical. One key process in battery manufacturing is resistance welding, which joins thin copper or aluminum tabs to cell terminals or busbars. This step must be performed with extreme precision to ensure electrical integrity and mechanical strength.

The electrode material and design directly impact weld quality, production efficiency, and long-term battery performance. While conventional solid copper and brazed electrodes are still commonly used, they often fall short under the thermal and mechanical stress of modern battery production.

This is where NDB (Non-Defective Bonding) electrodes stand out. Designed to minimize defects and extend service life, NDB electrodes—particularly those with tungsten, molybdenum, WL10, or TZM alloy tips—are increasingly recognized as the superior solution. These advanced materials offer exceptional heat resistance, reduced deformation, and stable conductivity over thousands of weld cycles, making them ideal for high-volume, high-precision EV battery manufacturing.

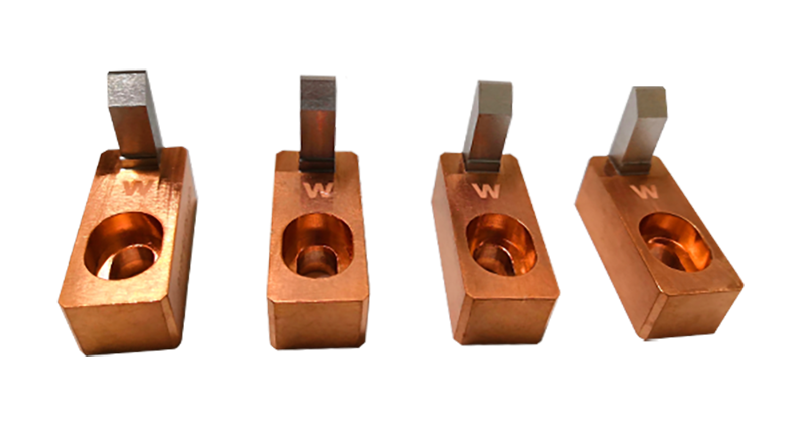

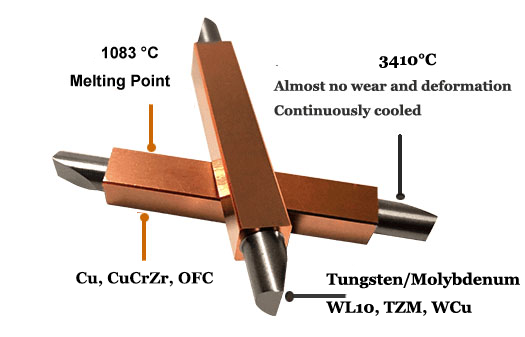

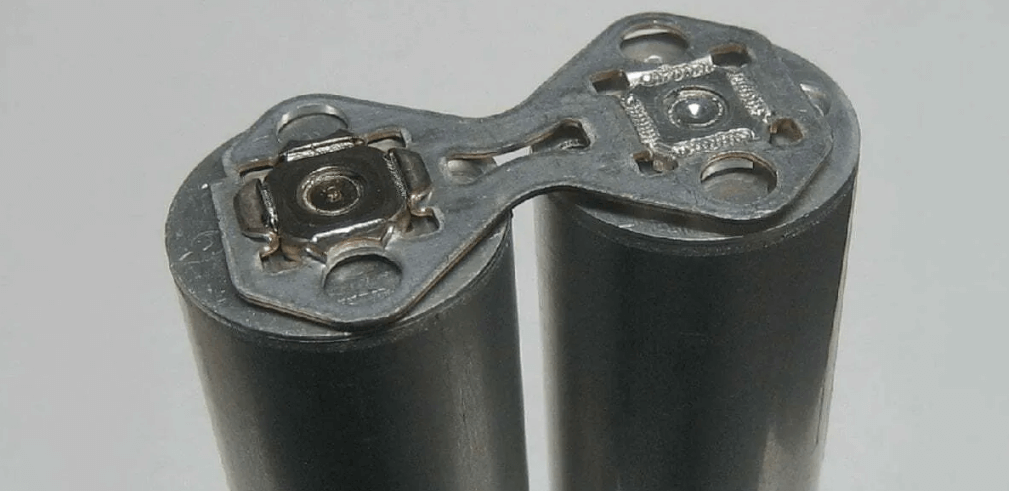

Electrode Material Structure: Shaft vs. Tip

Shaft/Base Materials

- Copper (OFC, CuCrZr): Used for their excellent electrical and thermal conductivity, these materials ensure efficient current transfer and rapid heat dissipation during welding.

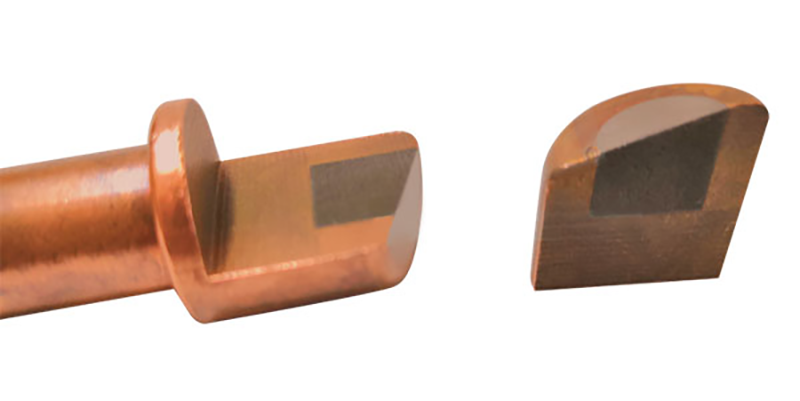

Tip Materials

- Tungsten (W): Renowned for its high melting point and wear resistance.

- Molybdenum (Mo): Known for thermal shock resistance and toughness.

- WL10 (1% Lanthanated Tungsten): Offers improved arc stability and tip life.

- TZM (Titanium-Zirconium-Molybdenum Alloy): Provides enhanced resistance to deformation and creep at high temperatures.

This separation allows each part of the electrode to be optimized for its specific function: the shaft for conductivity and cooling, the tip for durability and welding performance.

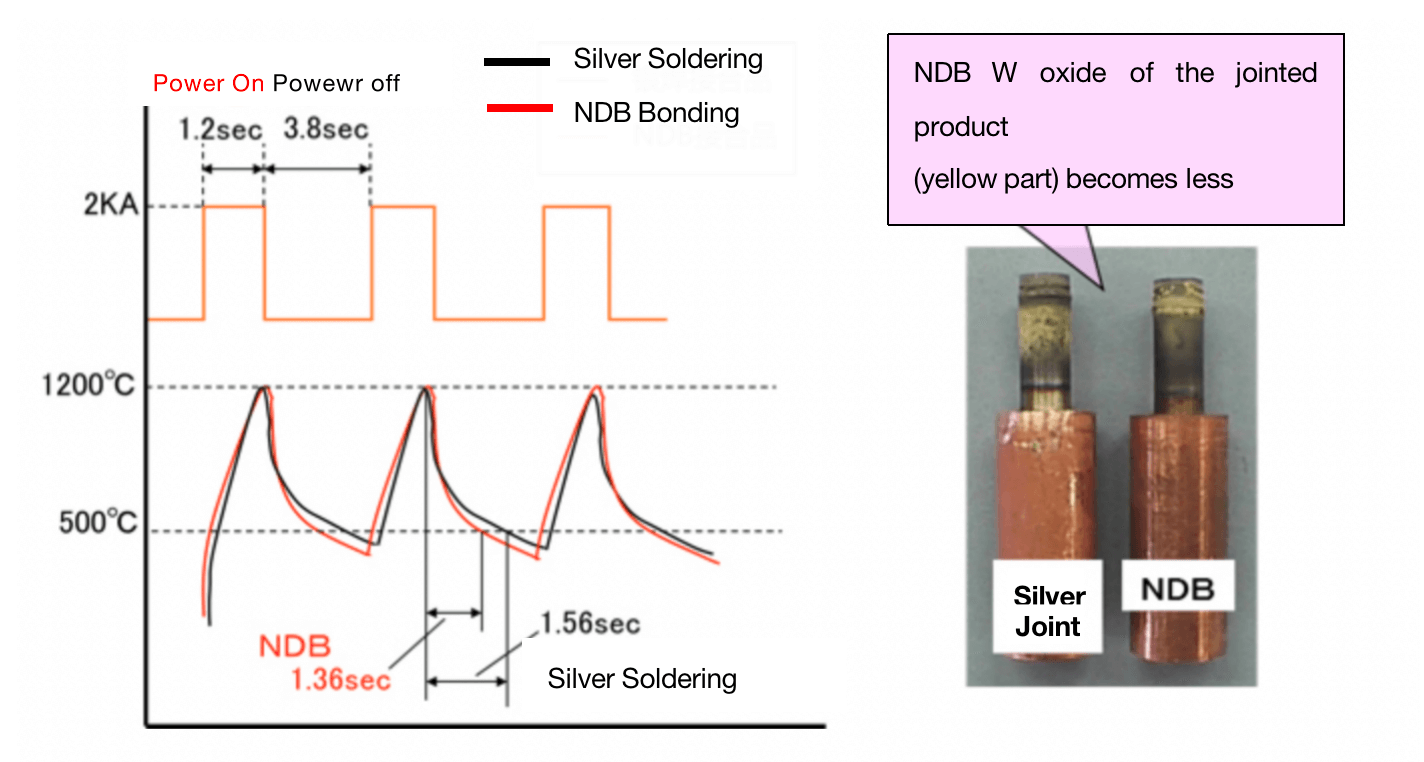

What is NDB Technology?

NDB (Non-Defective Bonding) is an advanced joining process that creates a seamless, void-free interface between the refractory tip and copper shaft. Unlike traditional brazing, which uses filler metals and can leave voids or weak spots, NDB technology produces:

- Extensive bonding coverage between tip and shaft

- High mechanical strength at the interface

- No filler metals or interfacial defects

- Improved heat transfer and mechanical stability

This robust connection ensures reliable performance under the demanding conditions of high-speed, high-volume battery tab welding.

Comparison: NDB Electrodes vs. Solid Copper and Conventional Brazed Electrodes

| Feature | NDB Electrode (W/Mo/WL10/TZM Tip) | Solid Copper Electrode | Brazed Electrode |

|---|---|---|---|

| Tip Material | Tungsten, Molybdenum, Alloys | Copper | Copper or Refractory Metal |

| Bonding Method | NDB (seamless, void-free) | None (solid piece) | Brazing (with filler) |

| Weld Consistency | High | Low (deforms quickly) | Moderate |

| Heat Dissipation | Excellent (copper shaft) | Good | Good |

| Wear Resistance | High | Low | Moderate |

| Suitability for Cu/Al Tabs | Excellent | Limited | Moderate |

| Maintenance Frequency | Low | High | Moderate |

Solid Copper Electrodes

While highly conductive, copper electrodes have a relatively low softening temperature. They tend to deform and stick when welding high-conductivity materials like copper or aluminum tabs, leading to rapid wear and increased maintenance.

Brazed Electrodes

Brazed electrodes use a filler metal to join the refractory tip to the copper shaft. The presence of filler and potential voids can limit heat transfer and mechanical strength, sometimes resulting in inconsistent welds and reduced electrode life.

NDB Electrodes

NDB electrodes, with their seamless tip-to-shaft bond, offer improved durability, weld consistency, and resistance to wear and contamination.

| Material | Key Properties |

|---|---|

| Tungsten (W) | – Extremely high melting point (excellent heat resistance) – Maintains tip geometry due to high hardness – Chemically stable, resists contamination from tab coatings |

| Molybdenum (Mo) | – High melting point (suitable for most battery welding) – Excellent thermal shock resistance – Tougher and less brittle than tungsten (better for vibration-prone setups) |

| WL10 (1% Lanthanated Tungsten) | – Enhanced electron emission for stable arc performance – Longer tip life due to improved wear resistance compared to pure tungsten |

| TZM (Titanium-Zirconium-Molybdenum alloy) | – High creep resistance (maintains shape under prolonged heat and pressure) – Excellent corrosion resistance (ideal for coated tabs and harsh environments) |

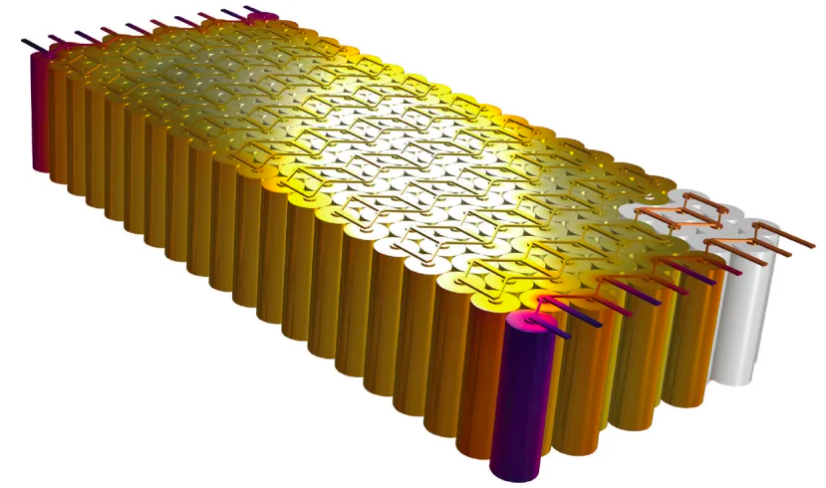

Applications in EV Battery Manufacturing

Tab Welding

Joining battery tabs to cells or busbars requires precision and reliability, which NDB tungsten and molybdenum electrodes provide.

Busbar Connections

Ensuring low-resistance connections between cells is crucial for efficient power distribution, achievable with these advanced electrodes.

Module Assembly

Integrating multiple cells into modules demands consistent weld quality, a strength of NDB tungsten and molybdenum electrodes.

Benefits in EV Battery Tab Welding

Consistent Weld Quality

- Stable current density and precise contact geometry for repeatable welds.

- Minimal electrode wear ensures uniform welds over time.

- Low spatter and clean welds, especially with WL10 tips.

Extended Electrode Life

- Longer service intervals than conventional types.

- Reduced downtime due to fewer electrode changes.

Superior Heat Management

- Efficient heat dissipation through seamless NDB interface.

- Prevents overheating and reduces risk of tip softening or burnout.

Clean, Reliable Welds

- No tip contamination thanks to chemical stability.

- No sticking to copper/aluminum tabs, reducing scrap rates.

Cost Efficiency

- Longer electrode life and reduced maintenance can offset higher initial investment.

- Fewer defective welds mean less rework and scrap.

High-Speed Automation Compatibility

- Suitable for high-speed, automated production lines.

- Stable performance in robotic welding systems.

Versatility Across Tab Materials

- Compatible with copper, aluminum, nickel, and zinc-coated tabs.

- Customizable tip geometries for various cell formats.

Enhanced Safety and Reliability

- Strong, consistent welds help minimize risk of electrical shorts or thermal issues.

- Reliable welds are essential for battery pack safety.

| Benefit Area | NDB W/Mo/WL10/TZM Electrodes | Solid Copper Electrodes | Brazed Electrodes |

|---|---|---|---|

| Weld Consistency | High | Low | Moderate |

| Electrode Life | High | Low | Moderate |

| Heat Management | High | Moderate | Moderate |

| Clean Welds | High | Low | Moderate |

| Cost Efficiency | High | Moderate | Moderate |

| Automation Ready | High | Moderate | Moderate |

| Material Versatility | High | Moderate | Moderate |

| Safety & Reliability | High | Moderate | Moderate |

Yolo NDB Electrode ,Your EV Battery Resistance Welding Solutions

At Yolo, we are dedicated to helping manufacturers achieve the highest standards in battery tab welding. Our NDB electrode solutions feature:

- Tip Materials: Tungsten, molybdenum, WL10, and TZM, selected for specific welding requirements.

- Shaft Materials: High-conductivity copper or CuCrZr for optimal current transfer and cooling.

- Custom Geometries: Tailored tip shapes for cylindrical, prismatic, and pouch cell formats.

- Rigorous Quality Control: Every electrode is inspected for bonding strength, surface finish, and dimensional accuracy.

- Technical Support: Our engineering team works closely with clients to optimize electrode selection and welding parameters for their unique applications.

Why Choose Yolo?

- Proven in the field by leading EV battery manufacturers.

- Full customization for any battery tab design or material.

- Fast response for technical support and sample requests.

8. Conclusion

In EV battery manufacturing, the right welding electrode is vital for consistent, high-quality production. NDB electrodes with tungsten, molybdenum, WL10, and TZM tips deliver precise, durable, and clean welds that solid copper and conventional brazed electrodes cannot match.

Yolo’s NDB electrode solutions empower manufacturers to achieve higher productivity, lower costs, and uncompromising battery quality. For tailored recommendations or to request samples, contact our technical team and experience the difference advanced electrode technology can make in your production line.

Contact Yolo for expert advice, custom solutions, or sample requests. Let’s build the future of EV battery manufacturing together!

Top Grade NDB Resistance Welding Electrode

Factory Direct Supply

Get premium NDB electrodes with tungsten, molybdenum, WL10, and TZM alloy tips—directly from our factory in China. We offer OEM/ODM support, custom designs, and competitive pricing to meet your production needs.