Sharpest Tungsten Needle for sale

Lead Manufacturer from China

If you’re working in microdissection, wafer testing, ion emission, or high-voltage discharge, selecting the sharpest tungsten needle is not just a matter of preference—it’s mission critical. In this guide, I’ll walk you through what makes a tungsten needle truly sharp, how to evaluate its precision, and where to source verified, customizable options backed by real-world data and engineering standards.

Quick Answer:

The sharpest tungsten needle typically features a tip radius of just 50 nanometers, offering unmatched precision for microdissection, semiconductor testing, and ion emission. These needles are produced using ultra-fine machining and surface polishing techniques and must meet tight tolerances of ±0.001mm to ensure consistent performance across demanding applications.

Table of Contents

What Defines the Sharpest Tungsten Needle?

Nano-Scale Tip Radius

The defining factor of a needle’s sharpness is its tip radius. In high-precision settings, a tip radius of 50 nanometers (0.05μm) qualifies as ultra-sharp.

🧠 Why it matters:

The finer the tip radius, the lower the contact area—making it ideal for clean cuts in microdissection, precise contact in electronics testing, or stable discharge in ion systems.

| Material | Typical Tip Radius | Application |

|---|---|---|

| Tungsten | 50nm | Microdissection, wafer testing |

| Platinum | 150nm | Biochemical sensing |

| Stainless Steel | 200–300nm | Standard probes, general industrial |

📍 Microscopic comparison of tungsten needle tips (Tungsten vs Platinum vs Steel)

Material Properties You Can Trust

Tungsten is chosen for its exceptional physical properties that make it suitable for demanding applications:

- Melting Point: 3,422°C – The highest of all metals.

- Hardness: 9.0 on Mohs scale – Ensures exceptional wear resistance.

- Purity: ≥99.95% required for scientific and medical use.

- Density: 19.25 g/cm³ – Provides rigidity and durability.

These values are verified across ASTM standards, ISO certifications, and scientific publications such as Nature Materials and Microscopy Today. Tungsten’s combination of superior thermal stability and mechanical strength ensures consistent performance even under extreme conditions.

Precision Manufacturing Techniques

A tungsten needle’s sharpness depends heavily on its manufacturing process. Advanced techniques ensure precision at nanoscale levels:

- Centerless Grinding: Guarantees consistent shaft diameter across batches.

- Micropolishing: Provides a smooth surface finish for non-stick applications in biomedical or electronic fields.

Ion Beam or EDM Tapering: Shapes ultra-sharp points with tip radii as fine as 50 nanometers.

- Measurement Tolerances: Controlled by coordinate measurement machines (CMM) to ±0.001mm accuracy.

Applications of Ultra-Sharp Tungsten Needles

Biomedical and Surgical Applications

Tungsten needles play a critical role in medical devices and procedures due to their sharpness and durability:

- Electrosurgical Devices: Non-stick tungsten needles minimize tissue damage during high-frequency surgery.

- Microdissection Tools: Ultra-sharp tips enable delicate operations in neurology or histology.

- Lab Animal Sampling: Facilitates clean microvascular access in small animals like mice or rats.

Semiconductors and Electronics

Tungsten needles are widely used in semiconductor testing and electronic applications:

- Wafer Testing: Maintains contact integrity under repeated probing cycles.

- Probe Stations: Used for chip-level conductivity testing in advanced electronics.

How to Choose the Right Tungsten Needle

Key Selection Criteria

Before ordering tungsten needles for your application, consider these factors:

- Tip Radius: As fine as 50nm for high precision.

- Tolerances: ±0.001mm recommended for consistent results.

- Length & Shaft Diameter: Customized based on application requirements.

- Material Composition: Pure tungsten (W), lanthanated tungsten (W-La), cerium-doped tungsten (W-Ce), or alloyed variants.

- Surface Treatment: Options include polished finishes, coatings, or sleeve-mounted designs.

- Packaging: Bulk orders, sterile kits, or custom configurations available.

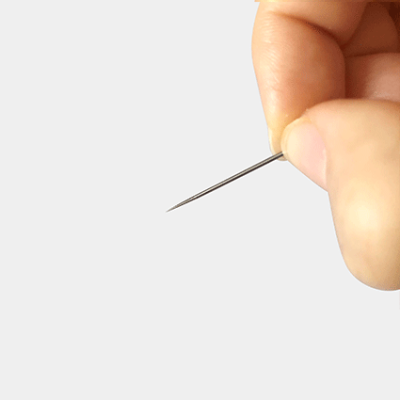

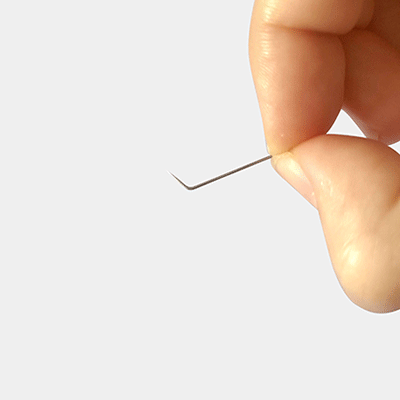

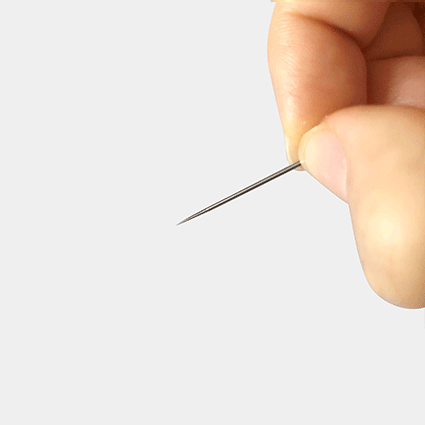

3 Head Types Selection of Tungsten Discharge Needle

- Arc/Round tip

- Flat tip

- Pointed/Sharp tip

Sharpest Needlepoint by Yolo

| Product Name | Tip Radius | Tolerance | Use Case | Customization | Price Range |

|---|---|---|---|---|---|

| Ultra-Fine Tungsten Needle | 50nm | ±0.001mm | Microdissection, wafer probing | Yes | Factory pricing |

| WLa20 Plasma Electrode Needle | 150nm | ±0.002mm | Plasma spraying, TIG welding | Yes | Factory pricing |

| W-Ce Ion Emitter Needle | 100nm | ±0.0015mm | Air purification, mass spectrometry | Yes | Factory pricing |

Straight form

C type/Bended form

Trusted Supplier and Factory Options

Why Work With YOLO?

YOLO stands out as a trusted supplier for ultra-sharp tungsten needles due to its comprehensive manufacturing capabilities:

- Factory-direct pricing ensures cost efficiency.

- Material traceability guarantees purity standards.

- Drawing-based customization allows tailored solutions for unique applications.

- Fast prototyping supports urgent projects alongside bulk production capabilities.

What is the Core Competitiveness of Yolo’s needle?

Raw materials

APT powder, tungsten discharge needle raw materials, we manufacture by ourselves, which the powder structure will definitely effect the ionizer results and service life. From aspects of quality control and materials cost, we have some advantages.

Straightness & Uniformity

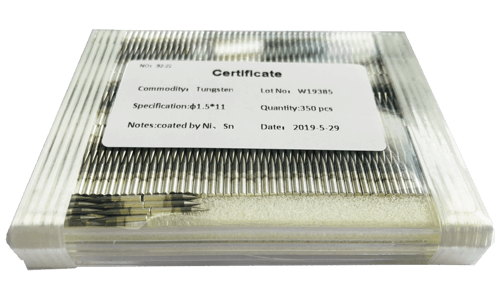

All raw materials with a diameter of less than 0.5mm are imported directly from Japan to ensure the uniformity and linearity of the contact probe. We use high-level technology to sharpen to meet Japanese standards.

Packaging

We aligned needle one by one neatly in vacuum and dust-free plastic box, ensuring each needle’s work performance is best.

Technical FAQs

Most frequent questions and answers

Tungsten needles are used in microdissection, semiconductors testing, plasma discharge systems, ion emitters, biomedical research, and precision welding due to their extreme hardness and heat resistance.

The sharpest tungsten needle has a tip radius below 100 nanometers—often custom-made for AFM probes, STM tools, or surgical microtools.

Yes! Tip size, angle, length, plating options, and packaging can all be customized based on drawings or specific application requirements.

You can purchase custom tungsten needles directly from specialized manufacturers like YOLO Materials who offer factory pricing alongside precision machining services.

Conclusion and Call to Action

Selecting the sharpest tungsten needle is critical for achieving precision in advanced biomedical research, semiconductor testing, ion emission studies, and other high-performance applications. By understanding key factors such as nano-scale tip radius and material properties—and sourcing from trusted manufacturers—you can ensure reliable results every time.

Ready to elevate your operations with ultra-sharp tungsten needles? Contact YOLO today for factory-direct pricing on custom solutions tailored to your exact needs!

Sharpest Tungsten Needle, Yolo's Own Raw Materials

Ready to get sharpest high precision tungsten needles tailored to your needs? Contact us today for bulk pricing, custom drawings, and factory-direct support.