Product

Spare Parts for Ion Implantation

With left hand competitive labor cost, right hand German quality standard, the produced plasma anode, plasma cathode, hollow anode, and nozzle in tungsten-copper materials, through NDB technologies, become a good partner of vacuum plasma spray gun.

Details about Spare Parts for Ion Implantation

Because it is a replacement part, the quality is always not satisfying you, wasting your precious time and increasing procurement costs.

Importantly, the effect of a beam path from the implanter system to wafer is always a little bit, even a lot, away from your standard deviation!

We all know that ion implantation plays an important role in semiconductor manufacturing, and the beam path greatly determines the effect of ion implantation. You may have a deep understanding of the impact of poor quality parts on your or your customers ‘semiconductor manufacturing, don’ t you?

Especially at a relatively high working temperature of 1400 degrees, strong electromagnetic fields, aggressive process gases and powerful mechanical forces. If you don’t open your eyes to identify the material, risks and losses will follow.

Molybdenum and tungsten metal will be the best materials selection for the implanter system.

However, low-level purity, uneven grain structure, low-density tungsten molybdenum raw materials will also lead to the ion can not be effectively generated and will not be guided precisely, and impurities along the beam path to the wafer.

Now, all the problems you have can be solved.

Yolo starts everything from raw materials production, also includes the tungsten and molybdenum metal for your ion implantation system.

With left hands: ultra-pure raw materials and right hands: Imported and domestic precision processing equipment and technology, combined with strict quality management system, Yolo can help you greatly improve corrosion resistance, material strength, high thermal conductivity.

This, ensure ions are generated efficiently, concentrated, accelerated and guided precisely at high speed to the target, especially ensure that the ions are free from impurities along the beam path to the wafer.

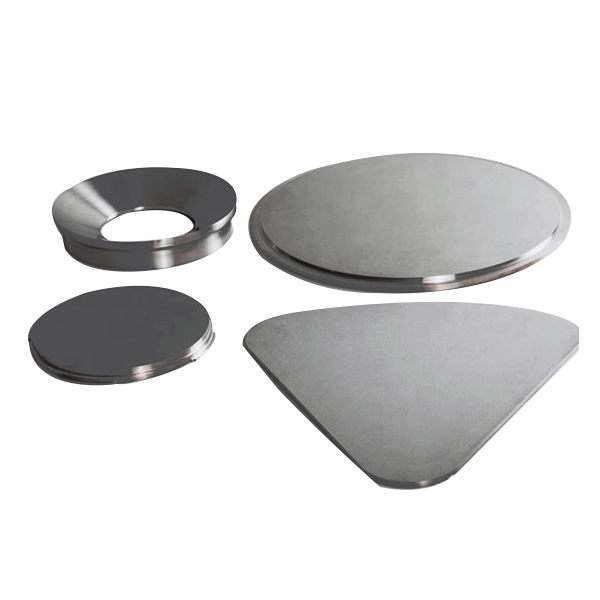

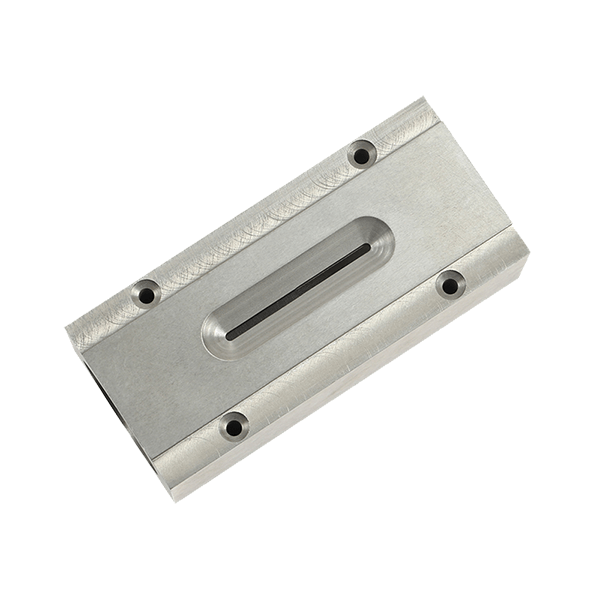

Certainly, Yolo can design, produce and process tungsten and molybdenum products of different specifications and shapes according to the requirements of customers, and can provide key tungsten, molybdenum and tantalum components and consumables for arc reaction chamber of ion implanter (large beam current, medium beam current, high energy).

At present, the products have been provided to well-known wafer manufacturers in mainland China, Taiwan, South Korea, Japan, and the United States.

We devote to Tungsten and Molybdenum production:

- Chambers (graphite, tungsten, molybdenum and allloys)

- Filaments (tungsten and tungsten alloys)

- Arcslits (tungsten, molybdenum and allloys)

- Holders (tungsten, molybdenum and allloys)

- Cathodes (tungsten, molybdenum and allloys)

- Spare parts (tungsten, molybdenum and alloys)