Product

Tungsten Wire

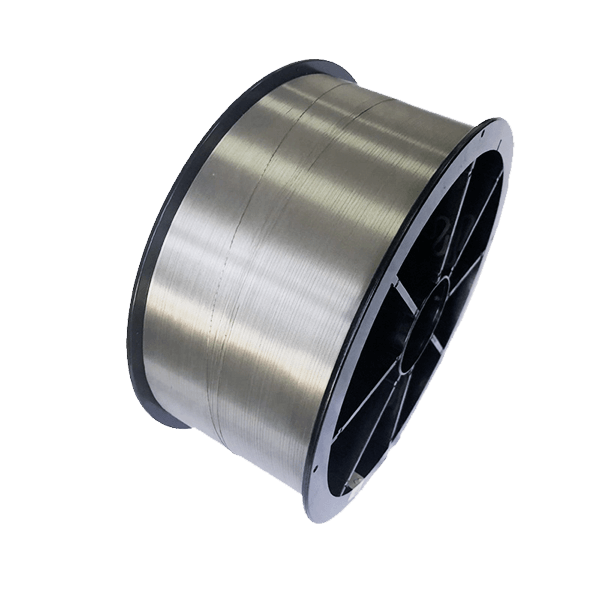

Yolo produce and supply thick and thin tungsten wire, Rhenium Tungsten (WRe), K-doped, with black, alkaline wash and electro polished white surface. Every spool wire production from raw materials

Details about Tungsten Wire

When it comes to using tungsten wire, cracks and brittleness are the enemies. And worse? They will be adversely affected by equipment stability and the production process.

Working with weak tungsten wires requires your production department to be on high alert. Any small mistake will cost you. The production team needs to strictly control the drawing temperature, speed, and processing variables. Also, sintering and forging play an important role in ensuring an efficient production process.

Tungsten Wire Lead Manufacturer from China

Electro Polished White & Black Surface

Tungsten Wire Details

Typical Size Capabilities for Wire

Wire ( Coiled or Spooled) – Diameter of .0002” (.005mm) and up

Purity

When specified – 99.95%

Surface

1. Electro Polished finish

2. Alkaline Washing finish

3, Black finish

Applications for Pure Tungsten

. Manufacturing of electric light sources and electric vacuum parts

. Used as high-temperature heating elements and high-temperature structural parts

. Used to make tungsten spiral for vacuum evaporation

. For integrators, fume purifiers, electrostatic precipitators, air purifiers, printers, copiers, etc.

Quality Standards of Molybdenum Wire

At Yolo Factory, every wire we produce adheres to strict

dimensional, mechanical, and surface requirements to ensure long-term performance.

- Diameter Consistency: Variation between two consecutive 200 mm segments ≤ 0.5% of nominal value.

- Linearity: For wire <100 μm, the sag height per 500 mm ≥ 450 mm;

for wire ≥100 μm, the arc height per 100 mm ≤ 10 mm. - Surface Condition: Smooth, defect-free, without cracks, burrs, or pits.

- Winding Performance: Wire remains unbroken during continuous winding.

Custom tolerance options, surface finishing (polished, ground, or bright), and ultra-fine fixed-length wire

(0.01–0.1 mm diameter, 10–300 mm length) are also available.

We tailor every order according to the customer’s exact specification.

Why Choose Us

Raw Materials

In China, only less than 1% of manufacturers of tungsten start with raw materials production. Fortunately, we are one of these few manufacturers. The overall particle uniformity of APT raw materials we use is better than that of other companies in the market, which can guarantee the overall quality.

Yolo: Uniform particle size

Some others particle

Flaw Detection

Yolo will have corresponding inspection for each process. 100% flaw detection to the 0.39mm thick wire end to confirm the crack. Under flaw detection, there are Grade A (eg: 2 crack points per 100 meters), B, C Grade. Any level wire below C will be removed, since the more cracks, the more easily the yarn are broken during processing.

Uniformity & Straightness

The quality difference of any two continuous 200 mm segments of tungsten wire does not exceed 0.5% of the nominal specification. For the tungsten wire ≤ 100um, the sag height of every 500mm shall be no less than 450mm;

For the tungsten wire ≥ 100um, the arc height per 100 mm chord length shall be ≤ 10 mm.

Drawing Process

Yolo’s advanced drawing equipment

Many other manufacture’s traditional equipment

A rolling mill introduced from Germany, which it can be deeply process the rod core, which can make the inside struction more uniform. Unlike the early traditional technology, are mainly surface processing.

What Industry Yolo Serve?

Besides being essential to the manufacture of coiled lamp filaments and surgical robotic cables, Yolo also supplies tungsten wire to other wide range applications.

Corona Discharge

Related: Tungsten Discharge Needle

Deposition

Related: Tungsten Coil Filament

Probe

Related: Tungsten Probe Tips

Furnaces

Lighting

Wire Cutting & Medical

What's Yolo's Solutions?

Evaluate customer requirements and quote

Evaluate customer requirements and quote

Provide samples for quality test

Improve the wire properties according to test results