NDB Electrode Yolo Materials Industry 20th, May 2023 1:00pm

What are the differences between NDB electrode and brazing electrode?

NDB electrodes create a direct, void-free bond between tungsten/molybdenum heads and copper rods without using filler materials, resulting in superior strength (120+ MPa), excellent conductivity, and longer service life. Brazed electrodes use a third metal as filler to join components, creating a potentially weaker interface with lower conductivity and shorter lifespan, but at a lower initial cost. NDB excels in high-precision, high-volume applications while brazing suits more budget-conscious, less demanding projects.

Choosing the right electrode can make or break your welding project. Let’s dive into what sets NDB and brazed electrodes apart, and why it matters for your specific needs.

Table of Contents

A Tale of Two Electrodes

Imagine you’re about to start a precision welding project. You have two electrode options in front of you: an NDB electrode and a brazed electrode. They might look similar at first glance, but their differences run deeper than meets the eye. These differences can significantly impact your project’s outcome, from the quality of your welds to how often you’ll need to replace your equipment.

What Makes an NDB Electrode Special?

NDB stands for Non-Defective Bonding – and that name tells you exactly what sets these electrodes apart!

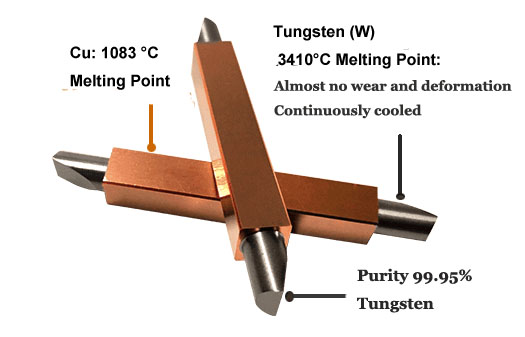

These premium electrodes are manufactured using advanced techniques that create a flawless, void-free bond between the electrode head (typically tungsten or molybdenum) and the copper alloy rod. The magic happens in a vacuum environment, eliminating any risk of oxidation or contamination.

The most impressive part? NDB technology directly bonds these dissimilar metals without using any filler materials at all. Think of it as creating a seamless connection that’s almost like the metals were born together!

This direct bonding is achieved through sophisticated metallurgical methods such as:

- Diffusion bonding

- Hot isostatic pressing (HIP)

- Carefully controlled temperature and pressure conditions

The result is a homogeneous interface with exceptional strength and conductivity properties.

How Do Brazed Electrodes Differ?

Brazed electrodes take a more conventional approach to joining metals.

Here’s how they work: the electrode head and copper rod are joined using a third metal – a brazing alloy that acts as a filler. The assembly is heated until this filler metal melts (while keeping the base metals solid), allowing it to flow into the joint and create a bond upon cooling.

While this tried-and-true method has been around for ages, it comes with an unavoidable reality: that layer of filler material creates a potential weak point. Even with modern brazing techniques, this interface can contain micro-voids or inclusions that might compromise performance over time.

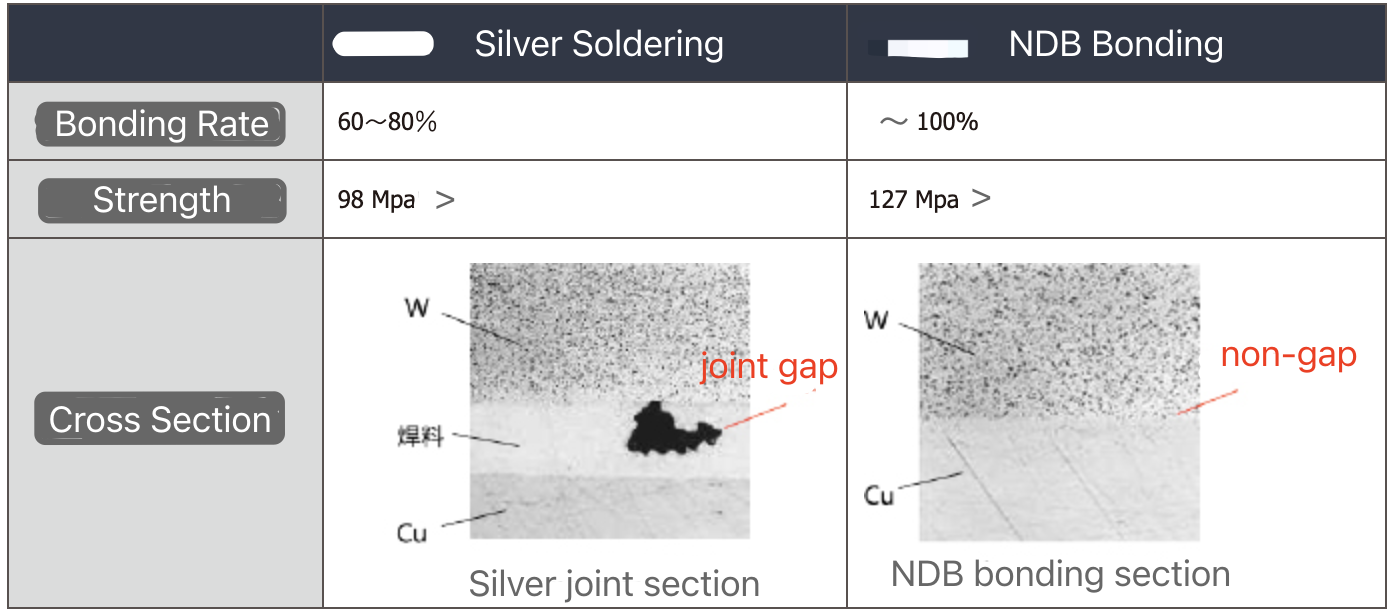

Seeing the Differences Up Close

Let’s break down exactly how these structural differences translate to real-world performance:

🔄 Joint Interface: Seamless vs. Layered

| NDB Electrodes | Brazed Electrodes |

|---|---|

| ✓ Void-free, seamless interface | ⚠ Contains a layer of filler material |

| ✓ Direct metal-to-metal bond | ⚠ Potential micro-voids or incomplete wetting |

| ✓ Bonding strength exceeding 120 MPa | ⚠ Lower overall joint strength |

| ✓ Excellent resistance to thermal cycling | ⚠ Possible stress concentrations at interface |

🔥 Heat Management: Efficient vs. Bottlenecked

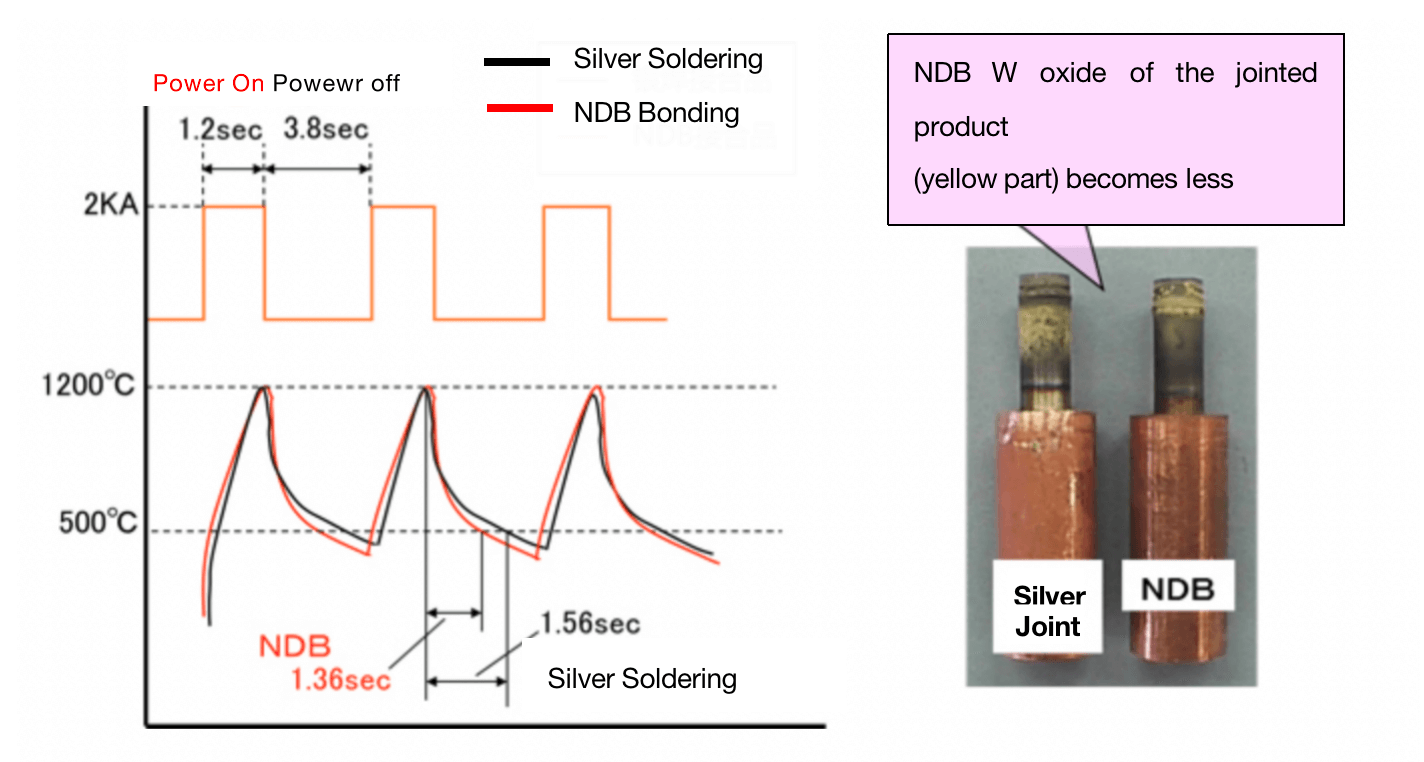

NDB electrodes shine when it comes to thermal and electrical conductivity. With no interfering filler layer, heat generated during welding dissipates quickly and evenly. This means:

- Faster cooling cycles

- More consistent temperature control

- Less risk of overheating

- Stable performance even in high-frequency applications

In contrast, brazed electrodes face a challenge: the filler material typically conducts heat and electricity less efficiently than the base metals. This creates what we might call a “bottleneck effect” at the joint. During intensive welding operations, this can lead to:

- Slower cooling

- Uneven temperature distribution

- Increased electrode wear

- Less consistent weld quality

⏱️ Lifespan: Marathon Runner vs. Sprinter

NDB Electrodes are built for the long haul. Their robust, void-free structure resists:

- Cracking

- Deformation

- Delamination

- Fatigue from repeated use

This translates to significantly fewer replacements and less downtime over the life of your equipment.

Brazed Electrodes can perform well initially but may develop issues sooner. The filler layer can become a starting point for:

- Micro-cracks

- Material fatigue

- Eventual failure under repeated thermal or mechanical stress

Choosing the Right Tool for Your Job

The best electrode choice really comes down to your specific needs. Here’s a quick guide to help you decide:

👍 When to Choose NDB Electrodes

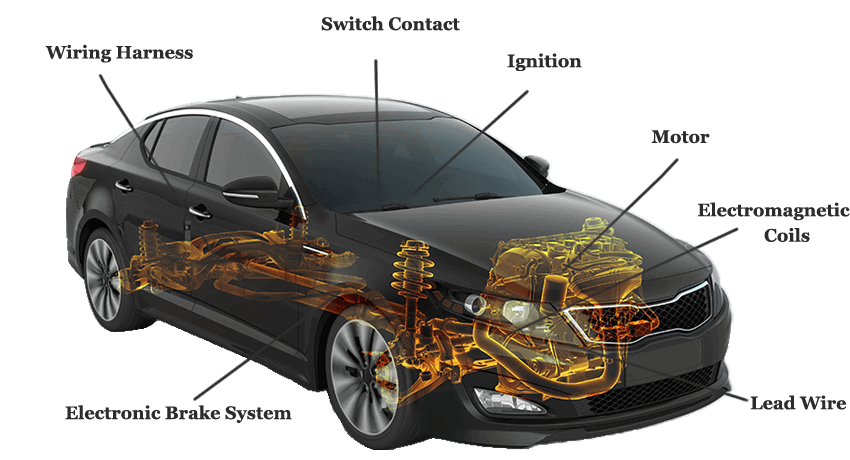

NDB electrodes are the gold standard for applications where reliability and consistent quality are non-negotiable:

- Automotive wiring harnesses – Where hundreds of connections must remain electrically stable for years

- Electric motors and precision sensors – When working with dissimilar metals that require strong, precise welds

- Medical devices – Where even minor defects could lead to critical failures

- High-volume production lines – Where minimizing downtime and maintenance pays off in the long run

👍 When Brazed Electrodes Make Sense

Despite the advantages of NDB technology, brazed electrodes still have their place:

- General spot welding with moderate mechanical demands

- Prototyping and short production runs where initial cost matters more than longevity

- Budget-sensitive projects with less demanding performance requirements

The Cost Equation: Initial Investment vs. Long-Term Value

Let’s talk money – because at the end of the day, that’s often what decisions come down to.

Upfront costs:

- NDB electrodes require more sophisticated manufacturing processes, making them more expensive initially

- Brazed electrodes are simpler to produce, resulting in a lower purchase price

Long-term economics:

- NDB electrodes typically last longer, reducing replacement frequency

- Less downtime for maintenance means higher productivity

- More consistent weld quality can reduce rework and scrap

For high-volume or mission-critical applications, the math often favors NDB electrodes despite the higher initial investment. Think of it like buying quality shoes – they cost more upfront but save money over time because you replace them less often.

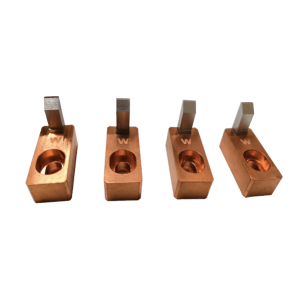

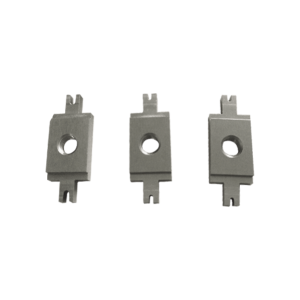

Our Premier NDB Electrode Solutions

We take pride in offering a comprehensive range of cutting-edge NDB electrodes designed to elevate your welding performance to unprecedented levels. Our products aren’t just electrodes—they’re precision-engineered solutions backed by years of research and development.

The WeldMaster Pro Series

🔷 Ultimate Bond Integrity

- Industry-leading joint strength exceeding 120 MPa

- 100% void-free interface verified through advanced scanning technology

- Metallurgically perfect transitions between dissimilar metals

🔷 Enhanced Tip Technology

- Proprietary densification process creating uniform internal structure

- Ultra-smooth surface finish with roughness below Ra0.8

- Optional special coatings for specific applications

- Precision-machined geometries for optimal current density

🔷 Performance Advantages

- Up to 3x longer service life compared to conventional brazed electrodes

- Superior thermal stability even under high-frequency operation

- Rapid heat dissipation preventing tip degradation

- Consistent electrical performance throughout the electrode’s lifespan

Industry-Specific Solutions

🚗 Automotive Applications

- Battery tab welding electrodes with enhanced cooling channels

- Precision-tipped variants for fine wire harness connections

- Heavy-duty models for chassis and structural components

⚡ Electronics Manufacturing

- Ultra-fine tip electrodes for PCB and microcomponent assembly

- Low-resistance variants for sensitive electronic components

- Anti-static options for ESD-sensitive environments

🏥 Medical Device Production

- Biocompatible materials for medical-grade welding

- Ultra-precision tips for implantable device manufacturing

- Specialized configurations for difficult-to-weld biomedical alloys

🔋 Energy Storage

- High-conductivity models for battery pack production

- Specialized designs for lithium cell tab welding

- Reinforced variants for high-amperage applications

Quality Assurance & Support

When you choose our NDB electrodes, you’re not just buying a product—you’re gaining a welding partner:

- Every electrode undergoes 100% inspection and performance testing

- Comprehensive technical documentation and application guides

- Expert application support from our team of welding engineers

- Custom design services for unique welding challenges

- Rapid prototyping for specialized configurations

Ready to Experience the Difference?

Our technical team is available to analyze your specific welding requirements and recommend the optimal electrode solution for your application. Contact us today to arrange a consultation or request samples for evaluation.

Elevate your welding performance with our industry-leading NDB electrodes—where precision meets reliability.

Making Your Decision

When deciding which electrode is right for your needs, consider these key factors:

- Quality requirements – How perfect do your welds need to be?

- Production volume – Will you be welding constantly or occasionally?

- Budget constraints – What’s your balance between upfront costs and long-term value?

- Downtime tolerance – How costly would production interruptions be for your operation?

For more information about our complete range of welding solutions, visit our website or contact our technical support team.

Premium Resistance Welding Electrodes by YOLO

Our Advanced NDB Electrode Technology

Resistance welding electrodes are specifically designed for environments where stable conductivity and heat dissipation are essential. Our electrodes offer superior performance compared to traditional electrodes (such as copper, silver, and copper alloy electrodes).

⚡ NDB One-Piece Connection Technology

- Utilizes Non-Defective Bonding (NDB) technology without any additives

- Copper and tungsten metals perfectly integrated with no internal voids

- Connection strength exceeding 130 MPa

- Superior electrical conductivity and heat dissipation

🔧 Key Product Advantages

- Each electrode undergoes densification treatment for high density and uniform internal structure

- Uses high-purity tungsten and copper alloys as contact materials

- Electrode tips maintain continuous cooling, effectively managing heat load

- Extended electrode service life and reduced production costs

- Enhanced physical properties with rare earth elements, providing improved stability, hardness, and resistance to deformation

📋 Our Product Range

We produce a comprehensive range of resistance welding electrodes:

- NDB connection electrodes

- Copper-tungsten electrodes

- Copper-chromium electrodes

- Copper-zirconium alloy electrodes

- Copper-chromium-zirconium alloy electrodes

🔬 Custom Design Solutions

With years of specialized production experience, our engineering team can develop custom electrode designs tailored to your specific application requirements and operating conditions.

Experience the superior performance of our NDB electrodes

Yolo Materials Industry Co.,Ltd – Advancing welding technology through innovation