What Is a Tungsten Nanoneedle Used For?

Electron microscope view from Yolo’s tungsten nanoneedle

Table of Contents

- Quick Answer

- Understanding Tungsten Nanoneedles

- Applications of Tungsten Nanoneedles

- Biomedical Applications

- Semiconductor and Nanoelectronics

- Material Science and Engineering

- Energy and Environmental Applications

- Manufacturing Process of Tungsten Nanoneedles

- Advantages of Tungsten Nanoneedles

- Challenges and Limitations

- Future Trends in Tungsten Nanoneedle Research

- Why Choose YOLO for Tungsten Nanoneedles?

- FAQs

- Conclusion & Call to Action

Quick Answer

Tungsten nanoneedles are ultra-fine, needle-like structures made of tungsten, utilized in various high-precision applications. In the medical field, they serve in nano-surgery, targeted drug delivery, and advanced imaging techniques due to their ultra-sharp tips enabling precise cell penetration. In semiconductors and nanotechnology, they are essential for semiconductor probing, scanning electron microscopy (SEM), and nano-scale electronics testing. Additionally, in plasma and ion emission applications, tungsten nanoneedles are key components in plasma thrusters for spacecraft and ion beam generation for research purposes. Their exceptional properties, including high melting point, mechanical strength, and superior electrical conductivity, make them indispensable in these cutting-edge technologies.

Understanding Tungsten Nanoneedles

Tungsten nanoneedles are fabricated with extreme precision, often featuring diameters in the nanometer range. Their high aspect ratio and durability make them suitable for use in scanning probe microscopy, advanced medical diagnostics, and nanoelectronics.

Applications of Tungsten Nanoneedles

Biomedical Applications

Tungsten Nanoneedle for microdissection by Yolo

Tungsten nanoneedles play a crucial role in:

- Cell Penetration Studies – Used for delivering drugs or genetic material directly into cells.

- Electrophysiology – Recording neuronal activity with minimal tissue damage.

- Microdissection & Surgery – Facilitating highly precise incisions at a microscopic level.

Image Placement: Microscopic View of Tungsten Nanoneedles in Biomedical Research

Semiconductor and Nanoelectronics

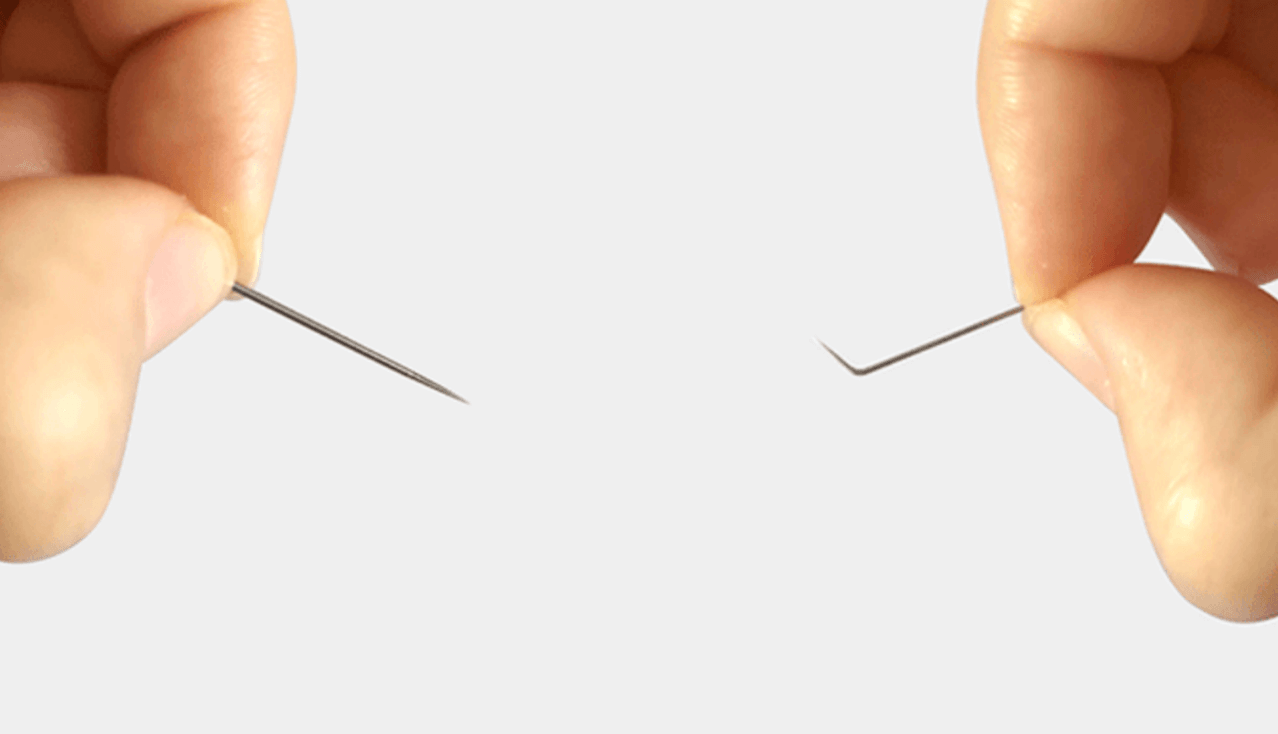

Test Tungsten nano needle probe

Test Tungsten nano needle probe

- Probe Needles for Wafer Testing – Ensuring high-precision electrical contact with microchips.

- Nano-Sized Circuit Prototyping – Used in atomic force microscopy (AFM) and nano-lithography.

Comparison of Tungsten Nanoneedles vs. Other Probe Materials

| Feature | Tungsten Nanoneedles | Silicon Needles | Gold Needles |

|---|---|---|---|

| Hardness | High | Medium | Low |

| Conductivity | Excellent | Moderate | High |

| Heat Resistance | Superior | Good | Poor |

| Reusability | High | Low | Low |

Material Science and Engineering

- Nanostructure Fabrication – Used in research to design new high-performance materials.

- Microelectromechanical Systems (MEMS) – Essential for fabricating micro-scale mechanical systems.

Energy and Environmental Applications

- Solar Cell Efficiency Enhancement – Improving light absorption in photovoltaic devices.

- Nanocatalysis – Supporting chemical reactions in hydrogen fuel cells and carbon capture technologies.

Manufacturing Process of Tungsten Nanoneedles

Tungsten nanoneedles are fabricated using advanced methods such as:

- Electrochemical Etching – Producing sharp, uniform needle tips.

- Chemical Vapor Deposition (CVD) – Allowing precise control over growth and properties.

- Focused Ion Beam (FIB) Milling – Shaping tungsten with nanometer accuracy.

Advantages of Tungsten Nanoneedles

- Exceptional Mechanical Strength – Withstands extreme conditions.

- Superior Conductivity – Ideal for electrical applications.

- High Precision – Enables nano-scale applications with accuracy.

- Long Lifespan – Compared to other nano-probes and micro-needles.

Challenges and Limitations

Despite their many advantages, tungsten nanoneedles face challenges such as:

- High Production Costs – Precision manufacturing is expensive.

- Fragility at Ultra-Thin Levels – May break under excessive force.

- Surface Oxidation – Requires protective coatings in some applications.

Common Challenges and Their Solutions

| Challenge | Solution |

|---|---|

| High Production Costs | Improved manufacturing techniques |

| Fragility | Reinforced structural modifications |

| Oxidation | Protective coatings like gold or platinum |

Future Trends in Tungsten Nanoneedle Research

- Advancements in AFM Probes – Increasing imaging resolution.

- Integration in Quantum Computing – Enabling next-gen computational technologies.

- Improved Biocompatibility – Expanding applications in medical implants.

Why Choose YOLO for Tungsten Nanoneedles

At YOLO, we specialize in manufacturing high-precision tungsten nanoneedles for all the above applications. We offer:

- Factory-Direct Pricing – Ensuring cost-effective solutions.

- Custom Design Services – Tailored to your specific application.

- ISO-Certified Quality – Adhering to the highest industry standards.

For more details, visit our tungsten nanoneedle page: YOLO Tungsten Nanoneedles.

FAQs

1. What makes tungsten nanoneedles better than other materials?

Tungsten nanoneedles offer superior hardness, electrical conductivity, and high-temperature resistance compared to materials like silicon or gold.

2. Can tungsten nanoneedles be customized for specific applications?

Yes, at YOLO, we provide custom tungsten nanoneedles tailored to precise dimensions, shapes, and coatings.

3. Are tungsten nanoneedles reusable?

Yes, due to their durability, tungsten nanoneedles can be reused multiple times, especially in semiconductor and nanoelectronics applications.

4. How do I place an order for tungsten nanoneedles?

You can contact us directly via our website YOLO Tungsten Nanoneedles for bulk orders and custom specifications.

Conclusion & Call to Action

Tungsten nanoneedles are revolutionizing industries, from medicine to semiconductors. If you need high-quality tungsten nanoneedles at factory-direct prices, YOLO is your trusted partner.

Find Your Tungsten Nanoneedle with Factory Price!

YOLO Company Introduction

Building upon the remarkable properties of tungsten needles, YOLO introduces high-precision tungsten needle solutions tailored for advanced scientific and industrial applications.

Comprehensive Applications

YOLO’s fine tungsten needles, with tip sizes starting from 5 microns, excel in diverse and demanding fields:

- Medical Minimally Invasive Surgery: Ultra-fine tips enable extremely precise surgical interventions with minimal tissue damage.

- Ablation Electrodes: Precise electrical targeting for medical procedures, particularly in cancer treatment and neurosurgery.

- Semiconductor Testing Probes: High-precision electrical characterization of microchips and electronic components.

Manufacturing Excellence

At YOLO, we control the entire production process from raw material refinement to final machining, ensuring stable quality and high precision. Our tungsten needles are available in ultra-fine sizes starting from 5µm, meeting the most demanding application requirements. We offer comprehensive custom machining services, including:

- Precision bending

- Specialized slotting

- Advanced coating techniques

- Precision grinding

- Custom tip shaping

Sharpest Tungsten Needle, Yolo's Own Raw Materials

Elevate your work performance with our sharpest tungsten needles by Yolo’s own tungsten raw materials! Ultra fine tip 5um with factory direct price!