What is the best materials in resistance welding for automotive?

The best material for resistance welding in automotive is composite electrodes combining copper with tungsten inserts. These electrodes offer superior electrical conductivity, thermal conductivity, and wear resistance, along with compatibility with diverse automotive materials. Their customizable properties make them the preferred solution for achieving efficient and high-quality welds in automotive manufacturing.

Outline

I.Introduction

A.Overview of resistance welding in automotive manufacturing

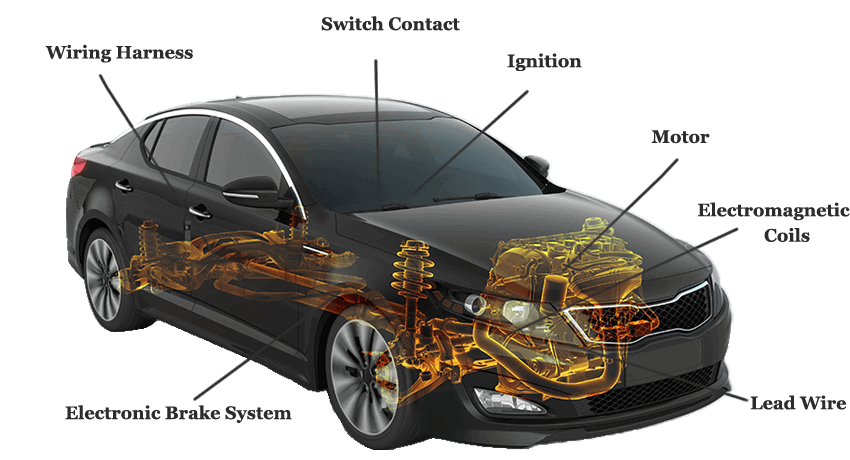

Resistance welding is a widely used joining process in automotive manufacturing. This welding method involves the application of heat and pressure to join metal components by passing an electrical current through them.

In automotive manufacturing, resistance welding is employed for various applications, including the assembly of body panels, chassis components, electrical connections, and other structural elements.

Its popularity in the automotive industry stems from its ability to produce strong, reliable welds efficiently and cost-effectively, contributing to the production of high-quality vehicles.

B.Importance of electrode material selection for optimal welding performance

The electrode material plays a critical role in determining the quality, efficiency, and longevity of the welding process. Different electrode materials offer varying levels of conductivity, thermal properties, wear resistance, and compatibility with automotive materials, affecting the overall welding performance and the quality of the welds produced.

Therefore, careful consideration of electrode material selection is essential to ensure optimal welding performance and the achievement of desired weld quality standards in automotive manufacturing

C. Preview of key factors

What is the key factors influence the resistance welding? Let is have a brief look firstly

- Conductivity

- Thermal properties

- Wear Resistance

- Compatibility

- Proper Design

II. Conductivity: The Spark of Efficiency

Next, please allow me to tell the key factors one by one. First one is: Conductivity.

A. Advantages of high electrical conductivity in electrode materials:

Hey there! Let’s talk about conductivity – You see, high electrical conductivity means quicker heat generation, better energy transfer, and ultimately, faster and more reliable welds.

B. Considerations for automotive welding applications

Now, when it comes to automotive welding, conductivity is a big deal. From steel to aluminum – with precision and strength.

So, choosing electrode materials that can handle the heat and keep the current flowing smoothly, even in the toughest welding conditions is crucial. Whether it’s body panels, chassis components, or intricate electrical connections, high conductivity ensures that every weld is spot-on and built to last.

C. Comparison of electrode materials based on conductivity:

So, how do different electrode materials stack up when it comes to conductivity?

Well, copper is like the gold standard here – it’s highly conductive and widely used in automotive welding for its reliability and efficiency.

But hey, let’s not forget about tungsten back cast copper composite materials too! They offering a perfect blend of toughness and efficiency for those high-stakes welding jobs. It’s like having a trio of conductivity champions, each bringing something unique to the welding party.

III. Thermal Properties: Handling the Heat

A. Importance of high melting point and thermal conductivity

Hey, let’s chat about handling the heat – a crucial aspect of resistance welding! Imagine your electrode material as the superhero cape that can withstand scorching temperatures and still keep cool under pressure.

That’s where a high melting point and thermal conductivity come into play. They’re like the ultimate heat-resistant armor, ensuring your electrodes stay strong and steady even when things get hot in the welding process.

B. Evaluation of electrode materials

Now, picture this: you’re in the automotive workshop, from fusing body panels to welding chassis parts, you need electrode materials that can handle the heat without breaking a sweat. High melting points and thermal conductivity ensure that your welds stay strong and stable, even in the toughest automotive welding conditions.

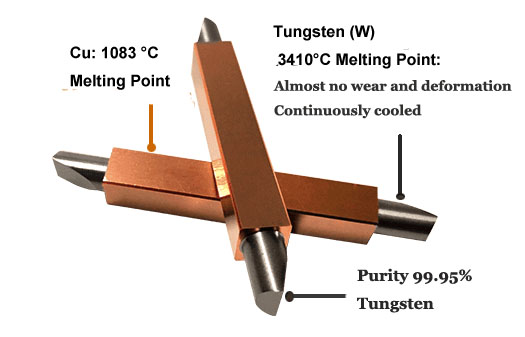

In terms of thermal performance, tungsten insert copper composite electrodes have the advantage over that old friend, copper electrodes.

Tungsten offers superior heat resistance and stability compared to copper, making composite electrodes better suited for high-temperature welding applications. This enhanced thermal performance ensures that tungsten insert copper electrodes can withstand the intense heat generated during welding without experiencing deformation or degradation, resulting in more reliable and consistent welds.

IV. Wear Resistance: Built to Last

Why wear resistance matters

Let’s chat about wear resistance – it’s like the secret sauce for keeping welding electrodes going strong! In the world of welding, electrodes face a lot of wear and tear from constantly joining metal components.

Wear resistance is what gives them the staying power to keep on welding without wearing down too quickly. It’s like giving your electrodes a durable shield against daily wear and tear, ensuring they last longer and stay reliable throughout your welding projects.

How wear resistance impacts automotive welding

They’re what keep your welding operation running smoothly, ensuring consistent and reliable welds day in and day out. Without them, you’d face constant interruptions for electrode replacements, leading to delays and headaches in the workshop.

C. Assessment of electrode materials for wear resistance:

When selecting the optimal electrode material for wear resistance, careful consideration is essential. While standard copper electrodes perform adequately, tungsten-inserted copper alloy electrodes elevate wear resistance to a new level. So, why is tungsten such a game-changer?

The unique properties of tungsten contribute significantly to its ability to withstand abrasive and erosive forces encountered during welding. Tungsten particles dispersed within the electrode material form barriers that hinder crack propagation and minimize material loss from friction and wear. Additionally, tungsten’s high hardness enhances the electrode’s surface strength, reducing wear and extending its lifespan.

Moreover, tungsten’s high melting point ensures its structural integrity and hardness remain intact even under the extreme thermal and mechanical conditions of welding operations. This characteristic is crucial for maintaining wear resistance over prolonged periods.

In summary, the incorporation of tungsten into electrode materials significantly enhances wear resistance by reinforcing the electrode structure, improving surface hardness, and maintaining structural integrity at high temperatures. This makes tungsten-inserted copper electrodes the preferred choice for automotive welding applications where wear resistance is vital for extended electrode lifespan and dependable welding performance.

V. Compatibility: The Versatility Factor

A. Importance of material compatibility:

Material compatibility is essential for producing welds of superior quality and longevity.

Incompatible electrode materials can lead to weak bonds, defects, and compromised weld quality, jeopardizing the structural integrity of vehicle components. Such issues not only affect vehicle performance and safety but also result in costly repairs and recalls.

Additionally, incompatible electrode materials may damage welding equipment, impacting productivity and increasing operational costs.

In summary, ensuring compatibility between electrode materials and automotive metals is crucial for achieving high-quality welds and maintaining efficient welding operations.

B. Comparison of electrode materials in terms of compatibility

Let’s explore how various electrode materials measure up in terms of their compatibility with automotive materials. A variety of materials commonly found in automotive components, including:

Steel

Used extensively in vehicle frames, body panels, and structural components.

Aluminum:

Found in engine components, wheels, and lightweight body panels.

Brass

Used in automotive fittings, connectors, and decorative trim.

Cast iron

Found in engine blocks, cylinder heads, and transmission cases.

Stainless steel

Used in exhaust systems, fuel tanks, and decorative trim.

Magnesium:

Found in lightweight components such as engine covers and transmission cases.

Is there an optimal electrode match for different metal materials? The answer is yes, see the list below.

Pure tungsten electrode

For Steel, Cold Rolled Steel, Aluminum, Magnesium, Nickel, Titanium/Precious Metals/Refractory Metals

Molybdenum electrode

(TZM, high temperature molybdenum)

For Coated Steel, Steel, Copper, Aluminum, Magnesium, Nickel, Titanium/Precious Metals

Lanthanated Tungsten Electrode

(WL10, WL15, WL20)

For Steel, Cold Rolled, Aluminum, Magnesium, Nickel, Titanium/Precious Metals/Refractory Metals

Cerium Tungsten Electrode

(WC20)

For Steel, Cold Rolled, Aluminum, Magnesium, Nickel, Titanium/Precious Metals/Refractory Metals

Copper Tungsten Electrode

(WCu W content 70%-98%)

For Coated Steel, Stainless Steel, Copper, Aluminum, Magnesium, Nickel, Titanium/Precious Metals

Tungsten Back Cast Copper

(Copper/Copper Alloy back cast tungsten)

For Cold Rolled Steel, Coated Steel, Stainless Steel, Copper, Aluminum, Magnesium, Nickel, Titanium/Precious Metals

VII. Conclusion

Choosing the right electrode material is crucial for quality welding in automotive manufacturing.

Considering all factors, tungsten-inserted copper alloy electrodes stand out as the top choice. They excel in conductivity, thermal performance, wear resistance, and compatibility with automotive materials. These electrodes ensure high-quality welds and long-lasting automotive components.

VIII. Additionally

A. The Impact of Electrode Design on Automotive Welding

In automotive manufacturing, electrode design greatly impacts welding efficiency and quality. The design of the electrode tip and shape can significantly affect the quality of welds, such as consistent weld penetration, strength, and integrity, reducing the likelihood of defects such as porosity or incomplete fusion.

Overall, electrode design is also crucial for optimizing welding performance and producing high-quality automotive components.

Our story

About YOLO

As a tungsten and molybdenum products factory, we prioritize quality and efficiency, allowing us to offer competitive factory prices without compromising on the excellence of our products. Whether you’re a small workshop or a large manufacturing facility, we’re committed to providing you with the customized spot welding electrodes you need to achieve outstanding welding results.

Contact us today to discuss your spot welding requirements and discover how our customized electrodes can enhance your welding processes at a competitive factory price.

Tungste Insert Copper Resistance Welding Electrode

Get Factory Price Start From Custom Size in China

As an expert manufacturer, Yolo offering high quality custom Spot resistance welder tips solution to evaluate your project!