Tungsten & Molybdenum

You can get high precision customized maching service here.

Leading Factory in China

Hot Sale

Our Solutions

Machining

Metal Bonding

Coating

Sharpening

Metal Molding

Customization

Why Choose Us

Start from Yolo's own Tungsten & Molybdenum Powder

Are you fed up with paying premium prices for inferior products?

Unlike most factories who purchase semi-finished materials to produce, we start production from the raw materials- APT Powder. The much cost savings passed on to you, the buyer.

Advanced Technology

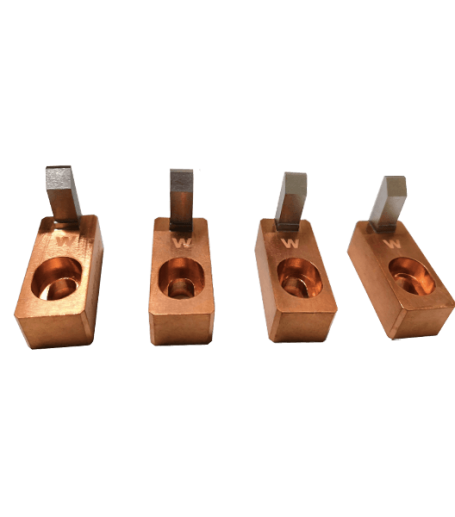

Do you still think the tungsten back-cast copper electrode with NDB (non-defective bonding) technology can only be bought in Germany? Never mind, Yolo will help you recover a lot of losses.

Excellent conductivity and hardness, but amazing unit price at Yolo.

Precision & Difficult

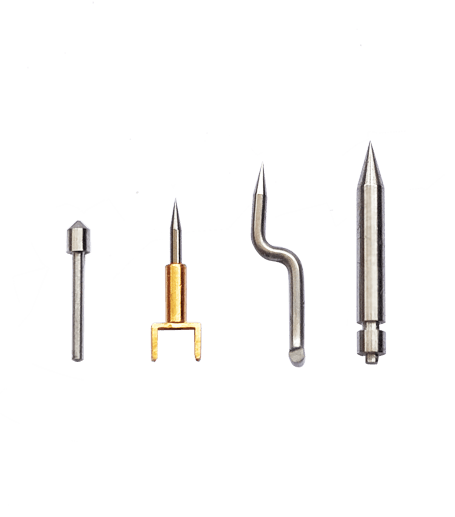

> Nano & Micro size probe needle (0.05mm diameter & 0.05um tip )

> 5mm diameter tungsten tube

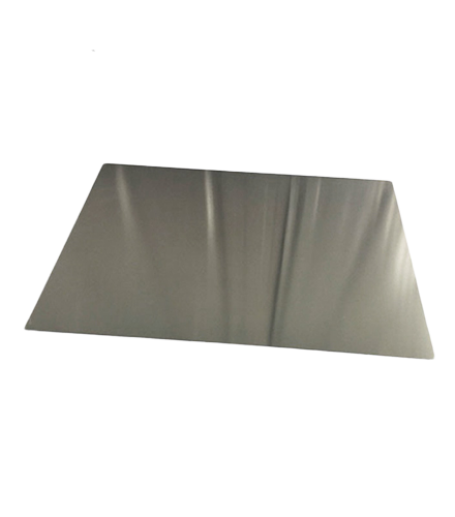

> 0.01mm thickness tungsten foil

We’re that accurate. We’re that light shines through the fog.

Risk free, no MOQ?

As low as one!

If you’ve felt the burn of wasted money on large quantity disappointing samples from other suppliers, feel free to try our risk-free offering!

Yolo bets one sample will win all your trust.

Industries We Serve!

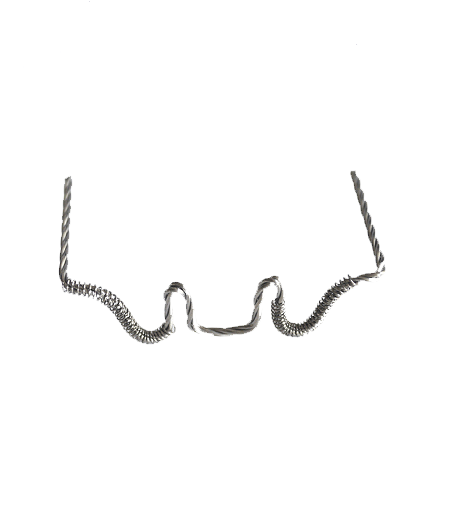

Tungsten and its alloys can be used to make rocket nozzles without cooling, ion rings for ion rocket engines, jet blades and positioning rings, hot gas reflectors and gas rudders.

The tip tungsten probe tip is controlled to a minimum of 0.05 microns (50 nanometers), which is mainly used in the semiconductor industry, such as wafer testing and chip testing of probe cards and probe stations.

Automotive manufacturing industry use lots of Tungsten back-cast copper electrodes (NDB technology: non-defense bonding) for resistance welding, such as welding steel plates and motors.

Customer reviews

I remember that when we first worked together, I was urgent for delivery, you drove the goods to the transit station and caught the flight to the USA on Friday.

Jeon kim

I had been looking for suppliers who can produce coated W needles for my customers. You have solved the problem very efficiently, my customers are very satisfied with the products.

April Herbst

I remember that when we first worked together, I was urgent for delivery, you drove the goods to the transit station and caught the flight to the USA on Friday.

Sandford

important things you should know

Questions And Answers

There is a saying that “Tungsten town, looking for Luoyang”. Our factory is located in Luoyang, a Midwestern city in China. A strategic position with the world’s largest reserve of molybdenum and the second highest source of tungsten globally.

As low as one! This is one advantage we offer that others can’t. If you’ve felt the burn of wasted money on disappointing samples from other suppliers, feel free to try our risk-free offering!

We cut out the middlemen in the end to end manufacturing process. Rather than obtaining semi-finished goods from other suppliers, we obtain our raw material of APT powder directly from its source.

If there is a loss caused by our unilateral improper operation, we will compensate with replacements or make a refund as appropriate.

These cost savings are then passed on to you, the buyer.

Mainly Germany, Japan, followed by the United States and South Korea. Plus some other European and Middle Eastern countries.

100% full inspection. Inspectors will check the finished product one by one, to ensure they adhere to all parameters.

All unqualified products that don’t make the cut are discarded.

We have an efficient Order Management System, from material preparation to machining, and finally to full inspection. Every stage of production is strictly monitored and controlled to give you a accurate delivery time.

If you’re a trader, we’ll share timely information on the industry. We’ll keep you up to speed on market trends and hot products on promotion.

If you’re the consumer, we’ll provide suggestions on material selection and machining methods in accordance with your specific industry and daily usage.