The Ultimate Guide to Tungsten Electrode Selection in TIG Welding

Tig Welding Yolo Materials Industry 26th, July 2023 15:00pm

How to judge the quality of the tungsten tig welding electrode?

1) No melting and burning during welding

High temperature resistance requires that the electrode does not melt and burn during the welding process. Otherwise, not only the electrode itself will be consumed quickly, but also the arc will drift, causing the arc to be unstable.

In addition, once the electrode is melted, the electrode material entering the molten pool will pollute the weld seam, produce welding defects, and affect the quality of the weld seam.

2) The work function is small

A strong ability to emit electrons requires a small work function of the electrode material. Especially at high temperature, it should have strong thermionic emission capability.

3) Good electrical and thermal conductivity

The large current carrying capacity requires that the electrode has good electrical and thermal conductivity, and can carry a large current without overheating.

4) Precision grinding

The surface of the electrode with good grinding processability needs to be ground. In this way, it has a certain dimensional accuracy and end angle, so as to ensure the clamping accuracy of the electrode, and reliable conduction, keep the arc stable, and improve the concentration of the arc heat.

5) Low radioactivity

Some substances used to improve the ability of electrodes to emit electrons are radioactive, so electrode materials with low radioactivity should be selected.

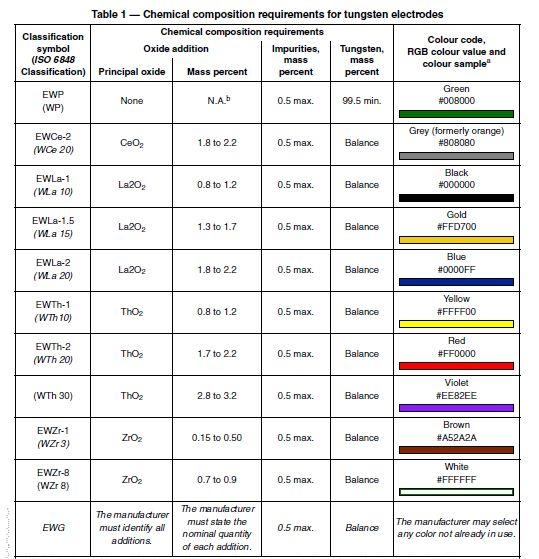

Color & Specifications

For the convenience of use, one end of the tungsten electrode is often painted with color for identification, thoriated tungsten is extremely red, cerium tungsten is extremely gray, pure tungsten is extremely green, and lanthanum tungsten electrode is blue.

Commonly used tungsten electrodes have diameters of 0.5mm, 1.0mm, 1.6mm, 2.0mm, 2.4mm, 3.2mm, 4.0mm, and other specifications.

There are many kinds, which tungsten electrode should I choose?

The electrode materials currently used include pure tungsten, thoriated tungsten, cerium tungsten, zirconium tungsten and lanthanum tungsten.

1) Pure Tungsten Electrode (WP)

The work function of pure tungsten is relatively high, ranging from 4.31 to 5.16eV, so it is difficult to start the arc in cold state. However, the melting point of tungsten is high, and the thermionic emission capability of tungsten is still very strong at high temperature. Once the arc is ignited, the arc is still very stable.

2) Thoriated Tungsten Electrode (WTh20)

Adding thorium oxide (ThO) with a mass fraction of 1% to 2% to pure tungsten greatly reduces the work function of the electrode, significantly enhances the electron emission capability, and improves the arc ignition and arc stability of the electrode.

It can also improve the current carrying capacity of the electrode and prolong the service life of the electrode.

3) Ceriated Tungsten Electrode (WCe20)

In order to reduce the radioactivity of the electrode, cerium (Ce) can be used instead of thorium. Practice has proved that adding cerium oxide (CeO) with a mass fraction of about 2% to pure tungsten can also significantly reduce the work function of the electrode and improve the arc ignition and arc stability of the electrode.

Especially in low current welding, the arc beam of the cerium tungsten electrode is thinner than that of the thoriated tungsten electrode, and the heat of the arc is more concentrated.

At the same time, the burning rate of the electrode is reduced, and the number of grinding times can be reduced. However, in high current welding, thoriated tungsten electrodes are more resistant to overheating than cerium tungsten electrodes.

4) Lanthated Tungsten Electrode (WLa20/15)

Golden lanthanum tungsten electrodes and blue head lanthanum tungsten electrodes have a wide range of applications and are the most promising welding electrodes.

It is used in the welding of aluminum and aluminum alloys and welding of carbon steel, stainless steel, silicon copper, copper, bronze, titanium and other materials.

Instructions for use of Tungsten electrode

Q: How to choose the diameter of tungsten electrode?

A: It is mainly selected according to the thickness of the weldment and the size of the weld current.

Q: How to choose the shape of the tungsten electrode tip?

A: If the selection is not good, it will have a great impact on the arc stability and weld shape. The end shapes include frustum, conical, hemispherical and planar.

When the welding current is high, the use of thin-diameter sharp-angled tungsten electrodes will cause the current density to be too high, causing the end of the tungsten electrode to overheat and melt and increase the burning loss.

At the same time, the arc spot will also extend to the tip cone surface of the tungsten electrode, which will cause the arc column to diffuse obviously, flutter and become unstable, and affect the formation of the weld seam.

Therefore, a tungsten electrode with a thicker diameter should be selected during high-current welding, and its end should be ground into a blunt cone angle (greater than 90°) or a cone with a flat top.

When AC tungsten arc welding is used, the tip of the tungsten pole is generally in the shape of a ball.

When DC tungsten arc welding is used, the tip of the tungsten pole is generally flat-bottomed and conical, with an angle of 30°~50°, so that the arc can have the strongest blowing force on the base metal, ensuring stable arc combustion and heat concentration during welding.

The size of the tungsten tip angle also has a certain influence on the penetration depth and width of the weld.

Generally, if the cone angle is reduced, the weld penetration depth increases and the fusion width decreases; on the contrary, the penetration depth decreases and the fusion width increases. The grinding direction should be parallel to the electrode axis, so that the generated arc can be more stable.

Tungsten Tig Electrode for Sale

Yolo, as a manufacturer of tungsten products in China, has over 20 years long history of producing large quantity tungsten tig electrodes for aluminum, stainless steel, orbital, small and precision metal parts welding. If any interests of tungsten tig electrode purchasing, please click the followed button to contact me or email us: dora@yolomet.com.

Get Price Now

Tungsten Electrode with Factory Direct Price